This is the second page of Cornish Miners Memories, due to the wonderful contributions written by several ex Cornish Miners.

You have my thanks, this is for the Cornish Miners around the world.

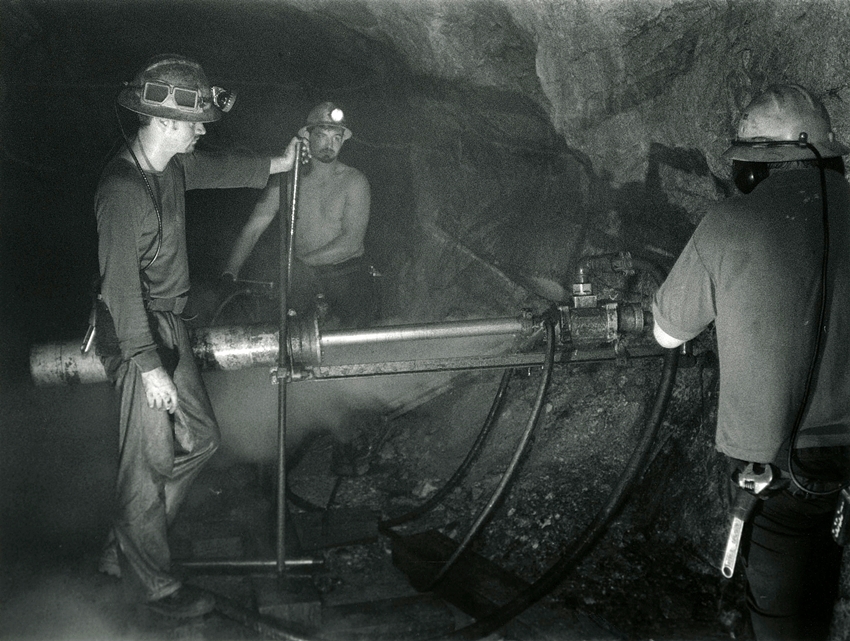

One of the Cornish Miners in the picture above is Billy Bettison. He has kindly written some lines on the life of a Development Miner.

The normal day in a Development Cornish Miners Life.

First of all have the crack with the boys waiting for the cage to go underground. Arrive at your level, then walk to your end or grab a loco and drive along the track. Collect your powder or explosives from the underground magazines. Then head off for the day.

The first job would be go to the face and wash down after previous days blast. Once all the dust is damped down go and look at the ground. If necessary go in with a pinch bar, bar any loose material down to make safe. Start the mucking out, usually with a Eimco or a Copco back mucker which loads the wagons behind. Once the wagons are loaded drive down the tracks to the grizzle area. Tip the wagons and then carry on until the face is cleaned out. If needed you would have to lay track which was the hardest part of the job. Blowing out the ground with a blowpipe to fit the sleepers in. Also you would have to put your services in, water and air pipes.

When this has been done, set up to drill. Two of you would be drilling, helping each other to color your holes off. Every instruction because of the noise was done by your cap lamp. Once drilling has been completed we would charge the face with Anfo if dry. But if the conditions were wet normal sticks of dynamite were used. Then bang and off she goes.

In the drilling you can use various cuts depending on ground conditions: 5, 6, 7 or 9 hole. Also if you want to throw the dirt back you would use a wedge cut.

When charging the face the lowest number would be in the middle of the cut. You would fire the cut first making the small hole bigger from the inside. Also time the holes from inside to out. So, the cut would go first then the box and diamond, stripping holes, eassers, side holes, top holes then last of all the bottom holes the lifters. Then do it all again the next day.

As a rule a development end is mined on waste parallel to the load /seam. Draw points are mined to the base of the lode where the lode is then stopped out in benches. However if it is mined on lode the old method of Cousin Jack timber ore chutes were put in to remove the broken ore.

Thank you so much Billy for this addition to Cornish Miners Memories 2.

Jonny Nicholls has kindly written a few Cornish Miners Memories for me about his work at South Crofty.

I ran a Boyles Bazooka underground coring rig. It was a small access compressed air driven 2 man drilling rig running TT 46mm drill string and core barrel with a slightly over sized reamer. The spec of the machine was up to 50m over 360 degrees but we ran her up to 130m over any inclination.

The rig was made up of a ram on a rail fixed to the wall with a rock bolt. Then the rig was mounted on a large acro prop to allow the rig to drop down to pull the drill string. This was done manually on shallow holes ie up to 50m but pulled with a air driven rod handler if a down hole was drilled. It was rated at 130 decibels in the open. But in a blind end with no vent it could be 200 so we used ear plugs and muffs. Pulling the rods by hand was very strenuous and I remember after about 2 weeks of it hardly being able to drive my car home due to cramps in my arms from the work.

Me and snitcher on 420 level used to drink 5 litres of re hydration solution every shift and still piss brown. The rig was a vast user of compressed air about 400 cfm which was piped under ground via the shaft in 8′ pipe. The miners in our vicinity used to complain of the massive usage of the bazooka when we went on as their air legs on the rock drills used to sag with all the air we used. We used to try and run on the back shift so as not to use all the air but then the trammers winged as we were using their air!

The set up of the rig was vital as you could be in one point in the mine drilling 10 different holes of various angles and length from a single drilling set up. I was most unfortunate to be placed by the great cross course fault on the 420 level for 5 weeks where it was very wet . A kind of Chinese water torture from the water dripping on my hat. We only had a small spot to roll a cigarette from our dripping nose to our dripping helmet brim.

The other thing we did on a Friday was drink. Several of us would meet up and you could always tell crofts men as they would shout at each other in the bar still thinking we had ear plugs in.. The response was a clinical eye contact as you still thought you had a head lamp on!!!!

Bloody funny in a night club.

Thank you so much Jonny for this addition to Cornish Miners Memories.