Cornish Miners Memories 3: Nicholas White, a former Wheal Jane Miner has written a piece for this page. As always I am very grateful to receive memories to publish, thank you so much.

Wheal Jane

A Miners View:

After many years adventuring and working abroad I had returned to Cornwall where I had been born. My mother had a cottage in the little village of Troon in the hills above Camborne. While I was looking for further adventures, in order to help out with the groceries I took a job at the Pendarves Mine literally just down the road from Troon. This was a reopening of the old mine to work the Tryphena lode where reasonable concentrations of tin and copper ores had been mined in the late eighteen hundreds.

I started at the bottom of the employment ladder, an onsetter. My work was to manage the loading and unloading of the men and materials on their way to and from the underground workings via the cage. Suspended on a steel cable in the shaft, the cage, capable of holding perhaps 20 men. Controlled by a series of electrical ring signals using a switch which communicated instructions to the winder driver.

Situated some 50 meters away in the winder house where the cable wound on to a massive drum. He, the winder driver, would position the cage according to the bell rings which designated the level to which the cage was to be lowered. One ring for ‘up’ and two rings for ‘down’ following the number of rings for which level to position the cage.

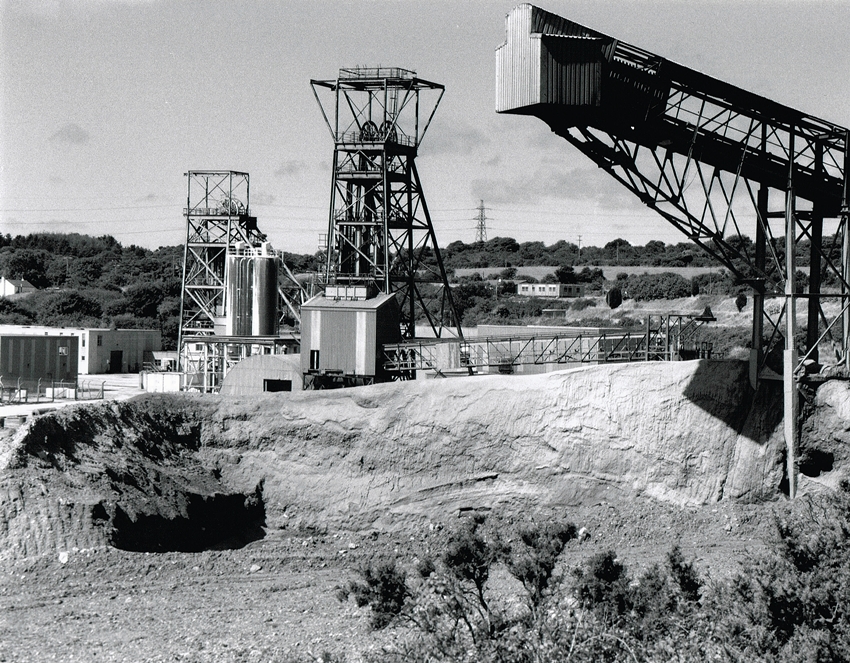

Some months went by and then news spread of the re-opening of a mine in the Chacewater area, Wheal Jane. The operating company, Goldfields, had built a ‘mining’ village above Truro. Here, following the South African model, were prepared to house their employees at a nominal rent. Wow, almost unheard of in Cornwall this was an opportunity not to be missed. I went!

By this time I had moved on, or rather ‘down’, into the mine and had some experience in the underground activity of ‘tramming’. This was moving the mined ore from chutes into the side-tipper trams which were then tipped into a ‘raise’. Here gravity dropped the ore to the lower reaches of the shaft then to be poured into a hopper in the shaft to be raised to the surface. Here it was tipped out to be transported to the mill for treatment.

I moved on and gained experience in handling the Holman Silver ‘Rock drill’. This compressed-air powered beast was the miners weapon of choice to penetrate the obdurate granite from which Cornwall is built.

Almost 300 million years ago, massive granite intrusions rose from the underlying magma and formed the Cornish peninsula. As it cooled, fissures formed and mineralized liquids forced their way up through these fissures. They in turn cooled and their minerals crystalized out forming the steeply inclined lodes running through the granite. Gold, zinc, copper, tin, arsenic and a sprinkling of other materials. All are present within these lodes. Initially discovered in the stream beds tin, silver and gold had been eroded out of the exposed lodes. Thus the treasures of Cornwall were discovered.

The resultant rush of mining activity brought prosperity to the South-West of England. The Poldark novels reveal much of the trials and tribulations of the Cornish mine owners. But this is not a geological lesson, this is my experience of Cornish mining.

The Wheal Jane ‘Main Lode’ inclines about 70 degrees to the south. The mine was developed with access tunnels some 25 meters through the hanging wall. Here the stopes could discharge the ore via scrapers into ore chutes. Working a scraper where twin brakes controlled the up and down movement was a hot and noisy experience. Dust billowed up despite the water-sprays which went to increasing the humidity leaving one with a fine layer of mud on every exposed surface.

The thermal gradient in the granite is quite steep with lots of water. Also with the mildly radioactive gas, Radon to contend with. Now to the real work – high-speed development! A two man team on drive development had a fixed routine. At the start of the shift we would descend to our level and walk to the face where we had left it drilled and charged with explosive. This was done at the end of the previous shift after everybody had been withdrawn and surfaced. The charges set throughout the mine were electrically fired leaving the fumes to be cleared overnight.

At the start of the shift, our work cycle started. If we had got it right the ‘lifters’, those explosives at the very bottom of the tunnel (and fired last) would have thrown the blasted rock back from the face. Then we could start to clear it using an ‘Eimco’ rocker shovel. This was a track-mounted compressed-air driven device which could throw a bucketful of shattered rock over itself into the tipper truck immediately behind.

Clear the blasted rock, lay another couple of meters of track. Then extend the services compressed air, water and ventilation pipes. Drill a few roofbolts if it warranted it after barring down any hanging rocks and then mark out the newly exposed rock face. The next job, set up our rock-drills on their airlegs and start drilling after a very careful inspection to check for any unexploded holes.

The drilling took time and care because a poorly marked and drilled face would not break cleanly and give us trouble on the next shift. We would usually be following a 3-inch diameter diamond drill hole. This not only gave the explosives a place to start the cut but acted as a safety probe.

Many of the old mines were not properly mapped out. So to drill or blast into an old shaft (often filled with water) would be a fatal event. After drilling the face, some 40 holes in a careful pattern to obtain a clean face after blasting. We would load the holes with explosives, dynamite or later ANFO (Ammonium Nitrate Fuel Oil) then set the detonators in a very carefully planned pattern. We used millisecond delays radiating outwards from the central cut to maximize the efficiency of the blast.

This working sequence would take just about the whole shift. Finally tired and dirty we would check the wiring one final time then make the final electrical connection to the central blasting ring as we left.

This was the life of the development miner. Work hard, play hard. Happy times!

I have received a new account from Stu Peters an ex-South Crofty Miner about a particularly bad day at the Mine. It is well worth a read, and a valuable addition to Cornish Miners Memories 3.

During the autumn of 1973 I went to work at South Crofty. On my first morning I rode the cage down to 380 at Robinson’s and met our shift boss John Gidney who walked me along the level. He showed me what went where, how the system worked etc. Then told me that I was to work on the spillage crew. I hadn’t a clue what he was talking about and when we reached Cook’s Kitchen side he introduced me to the other members of the team.

These were Charlie Merton, Adrian Roberts and Steve (to my shame I cannot remember Steve’s surname). We had a chat and Steve showed the way down the ladder way to the sump. He then instructed me in what seemed a pretty simple job. Apparently Mine Captain, Eddie Leake had found some difficulty in recruiting a full spillage crew so my arrival had been fortuitous.

My 3rd day 6.30am, found me at Cook’s Kitchen waiting for the cage down to 380. Dressed in a an old tweed jacket, my swimming trunks, boots, helmet, lamp, battery attached to a belt round my waist. I also carried a gallon of water in a plastic container.

I was accompanied by the three other members of the crew. Charlie Merton the winch driver, Adrian Roberts the fellow who made sure that the spillage re-entered the system and Steve who worked with me in the sump. It was a little draughty standing about under Carn Brea on a cool autumn morning, but entering the cage was like a balm, the warm, wet air, steaming as it rose from the depths.

I exited the cage on Cook’s shaft 380, the lowest working level in those days. The was Crusher in front of you. This was a brutal machine, its jaws smashing the large rocks down to a max of 8″. It shuddered now and then as it grappled with large, recalcitrant individuals of the rocky race. On the left an ore pass funnelled the ore to the crusher. Two and a half ton Granby wagons hauled by diesel loco’s stopped after their loads were tipped into said ore pass.

The air was filled with the fumes of diesel exhaust. To the right there was a floor mounted electric winch with a steel cable that stretched upwards at 45 degrees. This passed over a pulley and down to a one third of a ton steel kibble hung over an adjacent shaft that had been sunk to 400 level. Just beyond the kibble was a ladder way that led to the sump.

I had heard, listening to gossip, that there was some concern that the spillage was building in the box to the extent that it might hamper the lowering of the ore skips. Cook’s Kitchen shaft had been sunk to the 400 level to facilitate the filling of the rectangular steel ore skips. These would descend from the surface and stop just under the outlet from the crusher. The ore was released into the skips before being raised to the surface for onward transmission to the ore bins.

This was not a precise operation, the ore skips sometimes received a little more than they could carry. The extra ore overflowed and tumbled into a vast box. This was constructed of wood that extended 120′ from 380f to the floor of the sump at 400. Basically, a brattice to enclose the spillage. It was our job to remove the the spillage from the box so that none of the ore would be lost. Also to ensure that the skips could still fit into the box without being obstructed. The adjacent shaft had been sunk to 400 before a chamber (the sump) could be developed to facilitate the reclamation of the spillage.

The sump was approximately 20′ wide across the shafts by 15′ deep with the back being some 8′ above the floor. A ladder way was constructed to allow the ingress. Also to allow the exit of the two spillage crew members who would carry out the reclamation. Standing in the sump and looking at the western wall, the ladder way was on the left. Then, a rectangular pit about 4′ deep had been sunk between the ladder way and the south face of the brattice which extended some eight feet from the western wall. The box extended to the northern wall. A steel door had been let into the south facing side of the brattice just above the pit. The door could be opened and closed by the turning of a large steel wheel attached to a horizontal shaft that was geared with cogs to raise and lower the door.

Steve and I would take it in turns to hop down into the pit and receive the kibble. This would be swung across and pressed tight against the pit wall below the door. The door would be opened, the bucket filled with spillage, door closed, two tugs on the cable and the bucket disappeared up the shaft for Adrian to recycle. Cook’s side was warm and the sump was probably the warmest place in the mine; geothermal heat and water combining to form a hot and humid atmosphere. There was an upright conical, blue electric centrifugal pump in the pit to combat the ingress of water.

I took my turn in the pit, received the kibble, then pushed it into position and waited for Steve to open the door. Suddenly I received a ‘God Send’; a patter of small stones and dirt fell on me. Steve roared at me to get out and I was glad to have him grasp my hand pull me out of the pit. I caught a glancing blow from a heavier stone on my shoulder. As we ran back to the furthest point of the sump we could hear the crashing roar of an avalanche. Then we turned, and in the beam of our lights saw a cascade of stones, dirt and rocks fill the pit as the timbers above the door gave way. The avalanche was spreading along the western wall, eventually swallowing the ladder way and creeping towards us until it slowed to halt.

We moved carefully over to the base of the pile of rubble where the ladder way used to be. A glance upwards with our lamps showed no sign of the ladder way, nothing but fallen rubble. We were trapped. Standing at the foot of the pile of rubble, shouting before waiting to hear voices, just in case the ladder way could be negotiated far enough from above to allow us to hear some verbal communication. Nothing was heard so we retired to an old duck board that served as a croust seat. I think we were in shock for a while and did nothing as there appeared to be no immediate solutions.

Fortunately neither of us panicked and we decided to move to the foot of the avalanche with the intention of manually removing rubble that covered what should have been the ladder way. We worked away for an hour or so I suppose, being careful not set off a further fall, stacking the rubble behind us. Suddenly we started feeling sharp tingling sensations when we touched the water that had been steadily rising. We realised that the electricity cable to the water pump in the bottom of the pit had been severed.

We had no way of asking those on 380 to ensure that the power was turned off. This was not good, we were powerless to escape from the sump. We sat on the croust seat to swap stories to entertain each other. After a while we were obliged to prop it on some rocks to bring it clear of the water. We turned off our lamps to save the batteries and sat together, chatting in the absolute darkness, sipping at our water containers. The heat and humidity were debilitating. We used our lamps from time to time to check on the water level which was now creeping up our boots.

Unbelievably, we both dropped off to sleep for a while. I woke and wakened Steve and we discussed this phenomenon, perhaps it was the heat and humidity. Or carbon monoxide seeping from the rocks that had been blasted with dynamite from the solid rock face, transported to the crusher and the enormous pile of spillage. We had lost all track of time by now. At last we heard a muffled shout and we sloshed over to the rock pile keeping well away from the pit. We heard ‘Are you okay?’ and shouted back, ‘Turn off the water pump’. All was silent for what seemed an age before we heard. ‘Okay, it’s off’. We gingerly tried the water nearer the pit with our hands and found no tingling.

We went on removing the rubble at the site of the former ladder way. Meanwhile our rescuers were moving the same from the top end of the ladder way. As they made their way closer we could communicate and work together. The water kept rising, no faster though. Eventually a rope was dropped to us. Then our rescuers helped us pull ourselves up to safety on to the lowest undamaged platform of the ladder way. We were pleased to see Charlie and Adrian with a few other miners who had done all they could to get Steve and I out of trouble.

Great guys, all of them. I don’t remember much of the rest of the day, my light was handed in, I showered, dressed and went home. It was a surprise to find that it was getting dark outside. Seemingly an age since I had been at Cooks 380 at 6.30 that morning. Sadly there was an urgent need for repairs. No ore could be lifted until the spillage situation was attended to. So we were redirected to repairing the track on 380 followed by draining the slime bays.

Not the best job in the mine I suppose. We stood in mud and warm water literally up to our necks in an underground pond. Then opening a tap in the back, just above our heads so that slime could be released (all over us) from the slime bays above before turning the tap in the opposite to send a blast of fresh water upwards and keep the tap clear of debris. Repeat ad nauseam.

Fortunately, after a day of this we were reassigned to the now repaired spillage operation. Steve had moved on and I had a new companion in the sump. I left the spillage crew in in the New Year to broaden my knowledge of the South Crofty operations. So I went onto the night shift, tramming with Reggie Laity up on 240 I think. Bone dry but hard to make any money and daylight was becoming a memory. So in the spring I went on with that Master Machineman, Mike Osman. We were raising on 380, loved it, challenging and good money.

However, I had the feeling that Crofty would not survive for too long. Huge alluvial deposits of tin in Malaysia were being drag-lined out at a fraction of the cost of us chasing a narrow seam of cassiterite 380 fathoms underground. I said ‘farewell’ and moved on to another venture. I loved my time at Crofty. It is hard to think that the sump and 380 are almost two and a half thousand feet under water. But it is a long time ago and I wish all the best to anyone who is still around and recognizes himself in this story.

Stu Peters.

Thank you Stu, this account for Cornish Miners Memories 3 is very much appreciated.