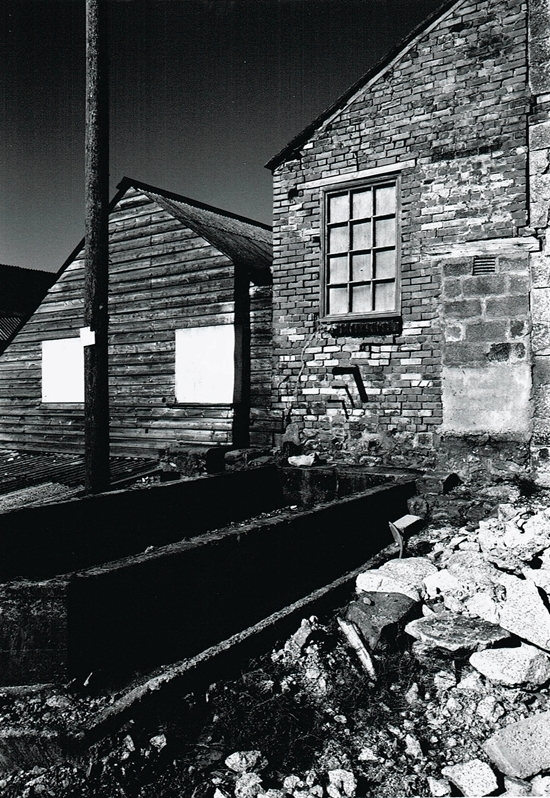

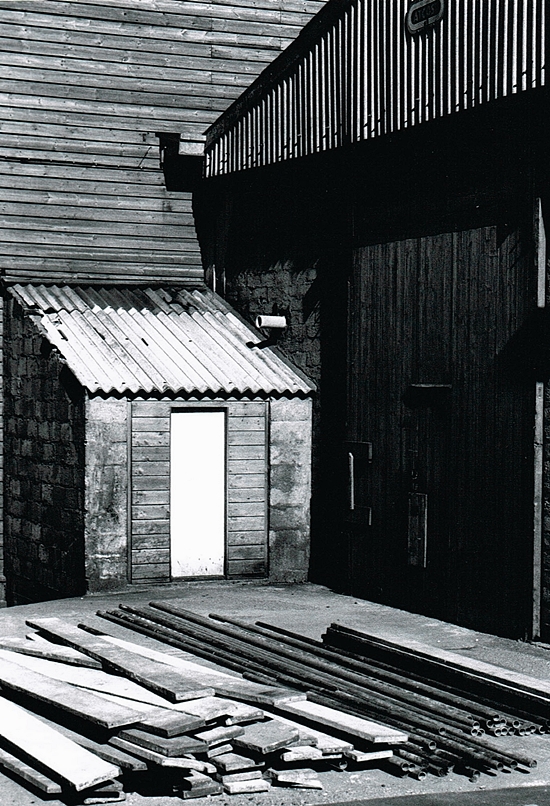

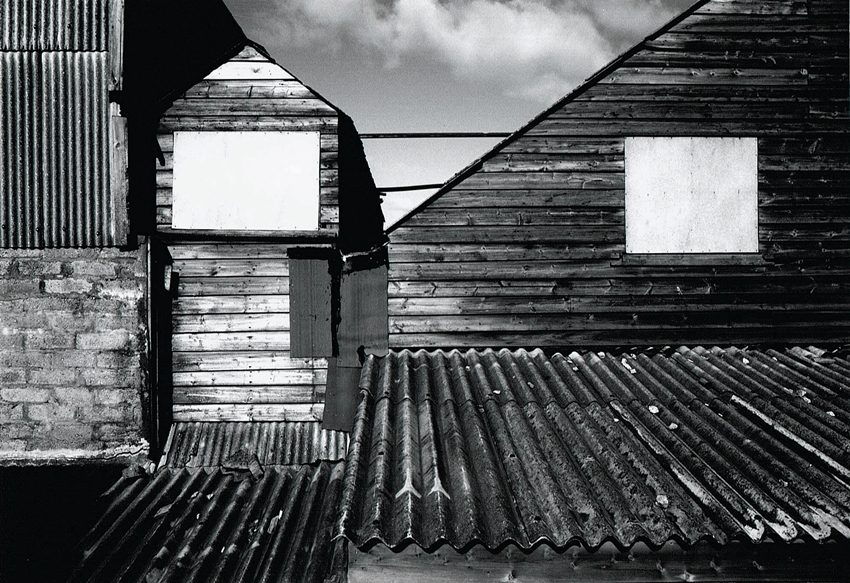

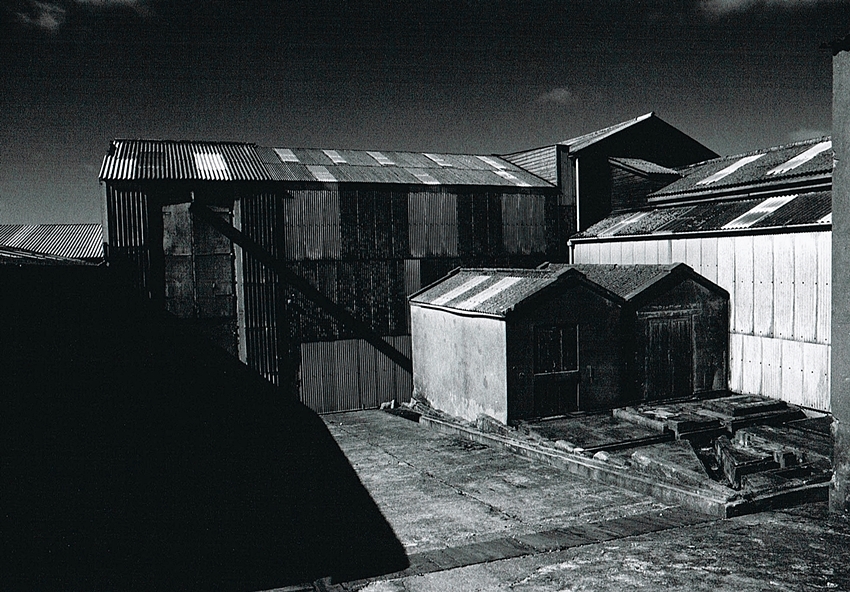

Geevor Tin Mine Gallery 3: More images of the buildings around the site. The wooden buildings sharp and angular make unusual and attractive photographic patterns.Once again Bob Orchard has supplied much of the information.

For someone with a camera the whole site is a great place to take detailed images.

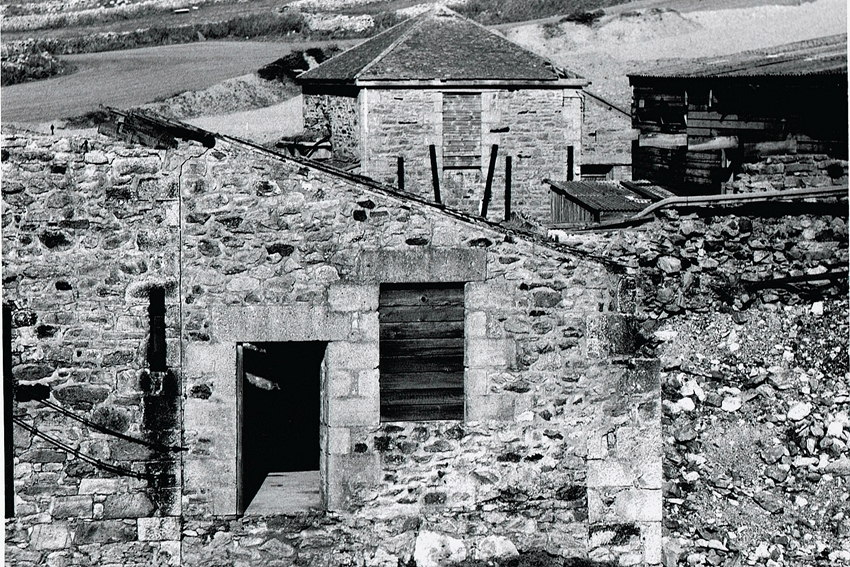

These were used to roast the tin ore which contained quantities of Arsenic. This was also recovered and sold as a valuable by product. The furnace was of a circular arrangement which rotated so the ore was burnt in an even pattern. These were in use upto the 1930’s when the improvements in the recovery process made them redundant.

The series of shallow concrete pits in the images were used to extract metallic copper from water rich in copper. This was the process of “cementation”, or quite simply depositing copper onto scrap iron. Just as a matter of interest, the worm & worm wheel that drove the vertical shaft that rotated the revolving hearth is still under the Calciner.

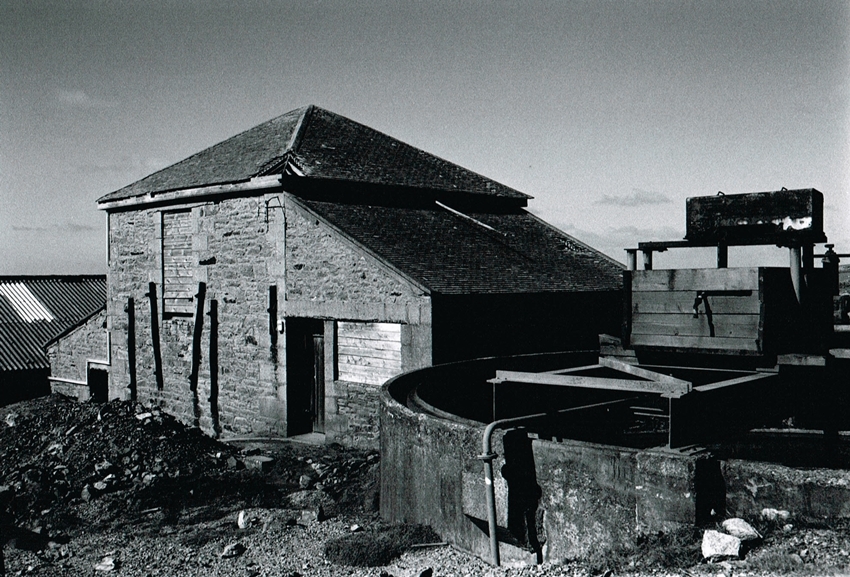

The bracing on the Calciner walls is to reinforce the walls from the heat inside. The western Brunton calciner in the foreground, and the eastern in the distance. The eastern Calciner interior has had the rotating hearth & rabble bars removed, also a concrete floor laid. It was here that an experimental “Buckman” frame was installed together with experimental hydrocyclones under the supervision of Doctor Birch & Mr Simms.

The round tank was a “thickener”, it contained slowly rotating rakes that continually scraped settled solids to the conical centre of the tank. The revolving rakes were driven by a worm drive mechanism supplied by R.O.Stokes. The mechanism had a very large spring on the worm drive shaft.

As the bed of settled solids built up the thrust on the spring increased and allowed it to push sideways tripping a micro switch, illuminating a lamp and ringing a bell. An operator would then manually raise the rakes or increase the rate of extraction of solids. The supernatent flowed on to a larger thickener, the 70′ tank. Just as a matter of interest, I fitted all new rakes, steel beams & overhauled the drive mechanism during the 1975 summer maintenance shutdown.

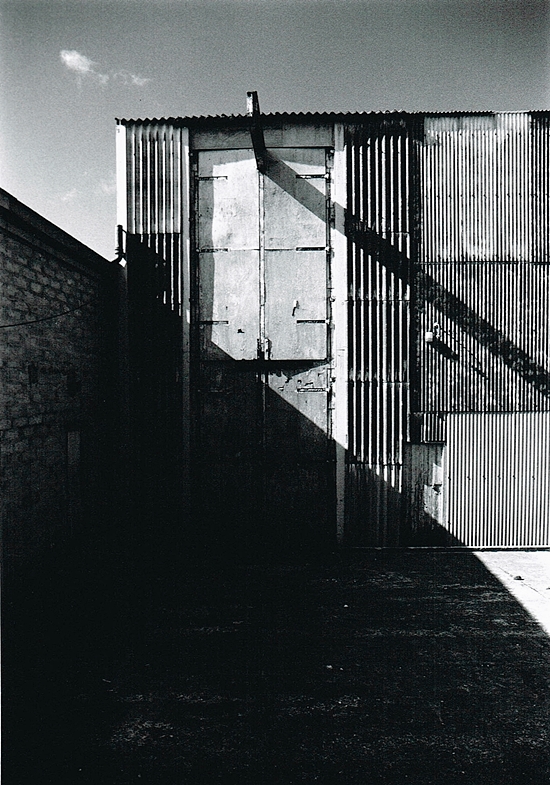

The building to left is the “Bottom fitting shop” which was the Maintenance shop for the mill. Also to the right this was the “HMS Plant”, Heavy Media Separation. Basically this plant used a slurry containing a mixture of atomised ferro silicon and magnatite at a density of 2.7 SG.

Run of mine rock was fed into it, if the rock was more that 2.7 SG it sank then collected as mineral bearing rock for further processing. If the rock was less than 2.7 SG it floated, was collected then sent to be screened as aggregate.

Again this is a R.O Stokes revolving thickener. Except that it is a “space-frame” with three bogies running on a circular track around the perimeter of the tank. One of the bogies being powered. The power supply running through a cable along the bridge to the center where there is a set of triple slip-rings & carbon brushes. This device allows the power to reach the driven bogie.

Mintech on-stream analyser, this was a method using radio active isotopes to detect to % of tin contained in various tailing streams. The tailings pulp stream was continually scanned. If the readings were outside of predetermined parameters alarms sounded.

The building on the right housed a sand pump. This was used when required to pump tailings to a hydrocyclone up on a timber structure & create a pile of sand. This sand was used by the mine masons for all building work. Also local builders would come to the mine for sand.