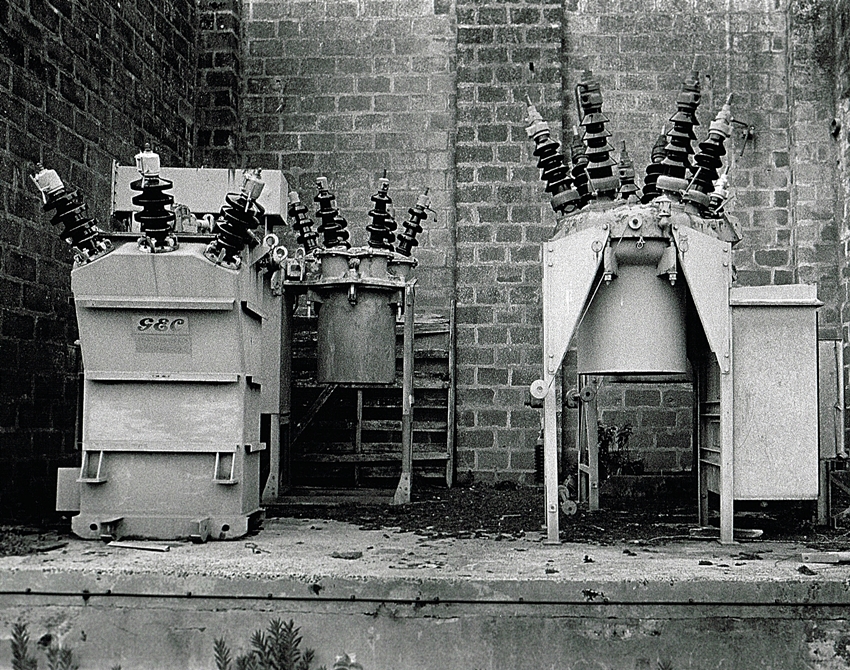

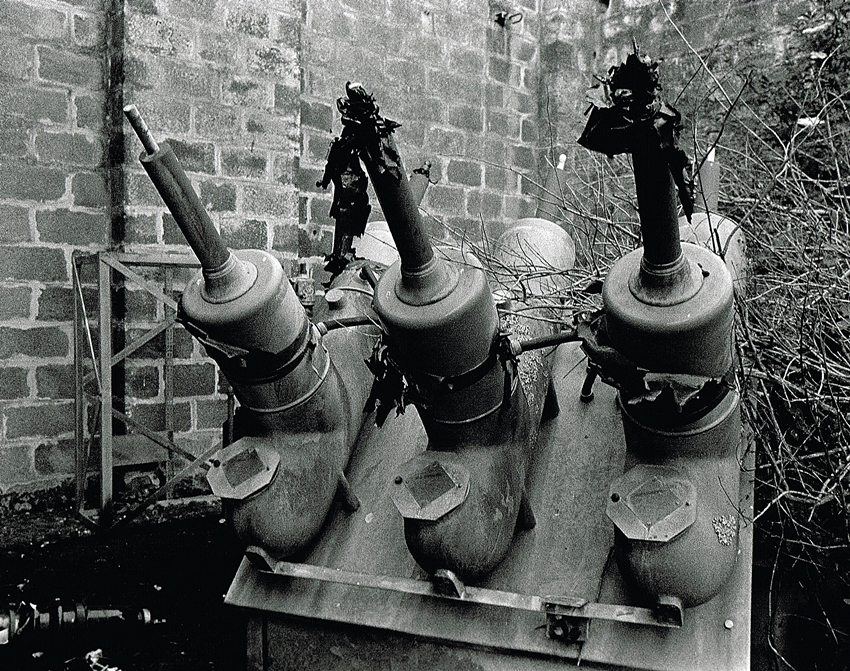

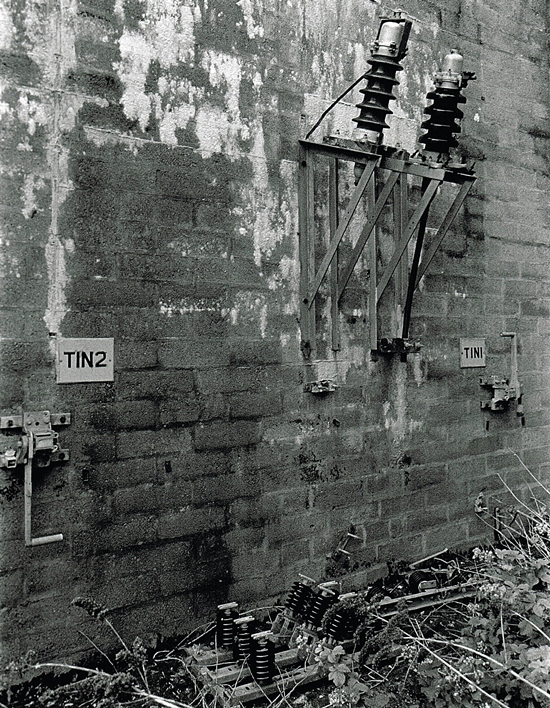

Hayle Power Station: Tracy and I were very fortunate to have a tour of the remaining facility in 2017. The Control Room along with distribution and storage areas are still in existence. My thanks go to Steve Kingstone for giving up his time to show us around.

On 13 March 1910, Harvey & Co of Hayle signed an agreement with the Cornwall Electric Power Company. For them to build a power station at the mouth of the River Hayle. Stage 1 of the station’s construction was completed by Carkeeks of Redruth.

It began on 7 May 1910, and was completed thirty weeks later on 12 December 1910 and power generation began.

Initially Hayle Power Station used a single 900 kilowatt (kW) Belliss & Morcom (B&M) steam turbine, supplied with steam by two Babcock & Wilcox boilers. This powered a Dick Kerr & Co alternator. During 1911 a 500 kW (B&M) was added, to use steam from the first turbine. This powered a Lancashire Dynamo alternator.

Another two identical generating sets were added between 1912 and 1913. Between 1914 and 1916, two further 3,000 kW Richardsons Westgarth & Company were installed. Each were supplied with steam by two Hancock & Wilco boilers. This brought the station’s generating capacity to 8,800 kW.

In 1928 a 7,500 kW British Thomson-Houston (BTH) turbo-alternator was added, supplied with steam from the Babcock & Wilcox boilers. In 1929, a 500 kW Parsons turbo alternator was moved to the station from Carn Brea Power Station, along with a Babcock & Wilcox boiler.

But they were never satisfactory and were removed by 1935. In 1932, a 10,000 kW English Electric turbo-alternator was added, provided for by a Sterling boiler.

In 1933 the station was finally connected to the National Grid, so electricity could be imported or exported by the company. A 300 kW English Electric turbo alternator was installed in 1935, primarily for pumping circulatory water around the station in case of a shut down. By this time the station’s nameplate generating capacity was 36,600 kW, but in 1936, the first six generating units were put up for sale as scrap. This brought the capacity down to 27,800 kW.

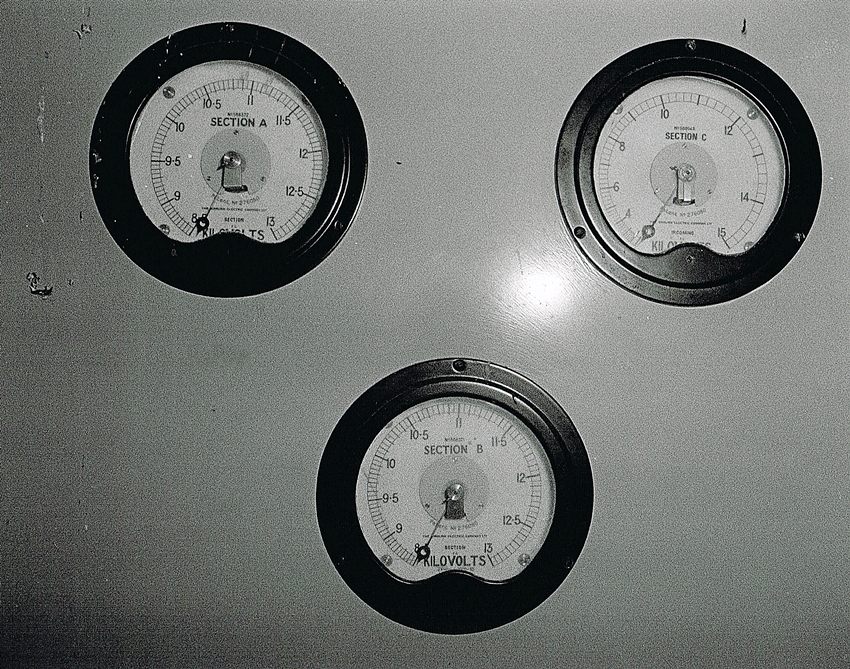

In 1938, Imperial Chemical Industries built the British Ethyl Works near to the power station, and the station provided it directly with electricity at 11 kilovolts. The works also used the station’s waste hot water. Associated Octel took over using the station’s water in 1948. In December 1938, heavy snow fell on England and for the first time the station was required to operate at maximum capacity.

In 1939, a 15,000 kW English Electric turbo alternator was added, provided with steam by a Sterling boiler. However this created problems with high water temperature and cooling problems on low tides. So a dam was built near the station.

In 1947, another 15,000 kW English Electric turbo alternator was added, provided with steam by two Sterling boilers. During 1949, a 20,000 kW English Electric turbo alternator was added, with a Yarrow boiler. In 1959, another 20,000 kW turbo alternator was added, this time provided by BTH, as well as another Yarrow boiler. This brought the station’s generating capacity to its highest ever, at over 70,000 kW.

In 1972, some of the station’s older generating sets were taken out of service. In September 1973, Associated Octel closed and ceased to take the station’s hot water. This, combined with large, modern stations taking base load, led to the station rarely being called upon to generate. Sadly it closed by the end of the year.

The station’s two chimneys were demolished in June 1981. The station’s turbine hall and boiler room were demolished the following December. To fit with an agreement made before the station’s construction, so the site was cleared following demolition.

The historical text was gained from Wikipedia.

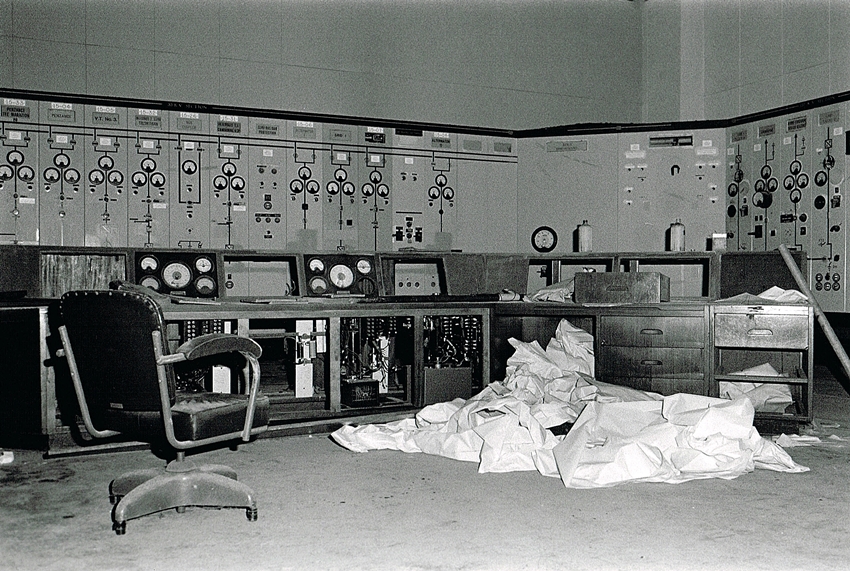

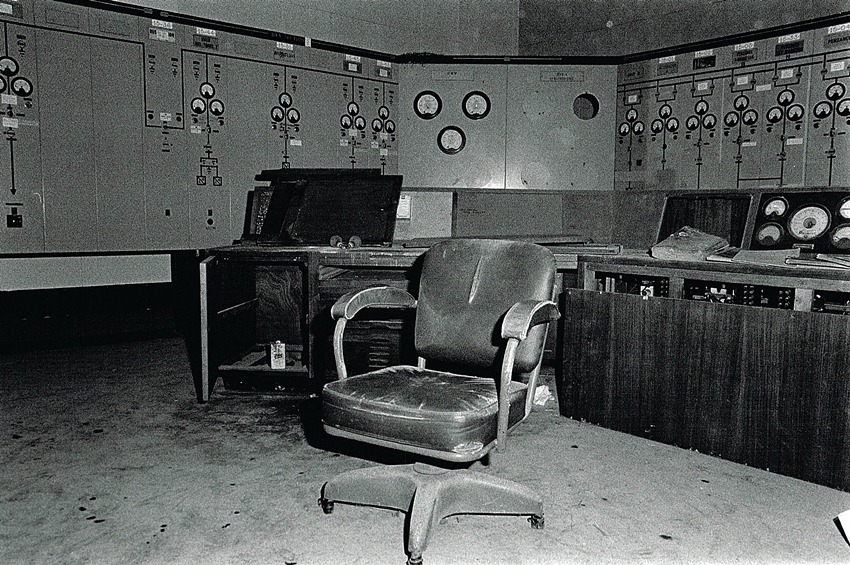

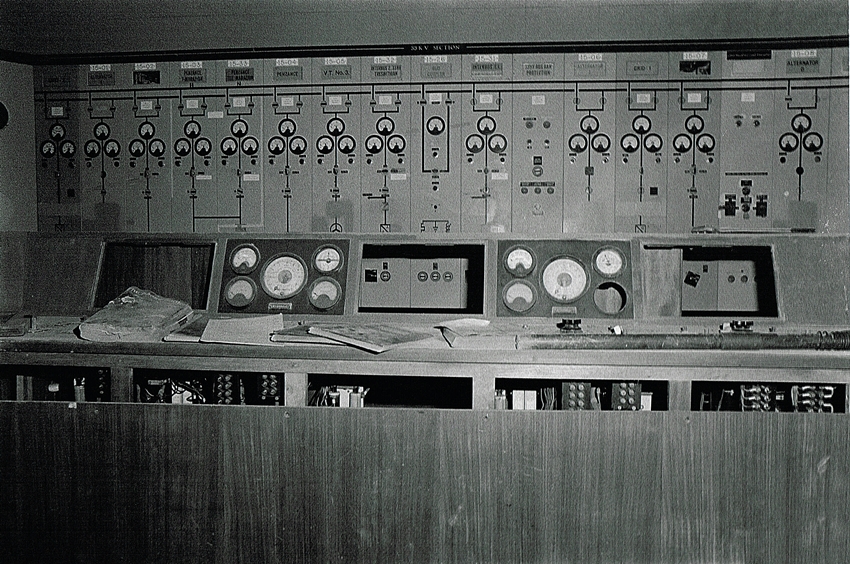

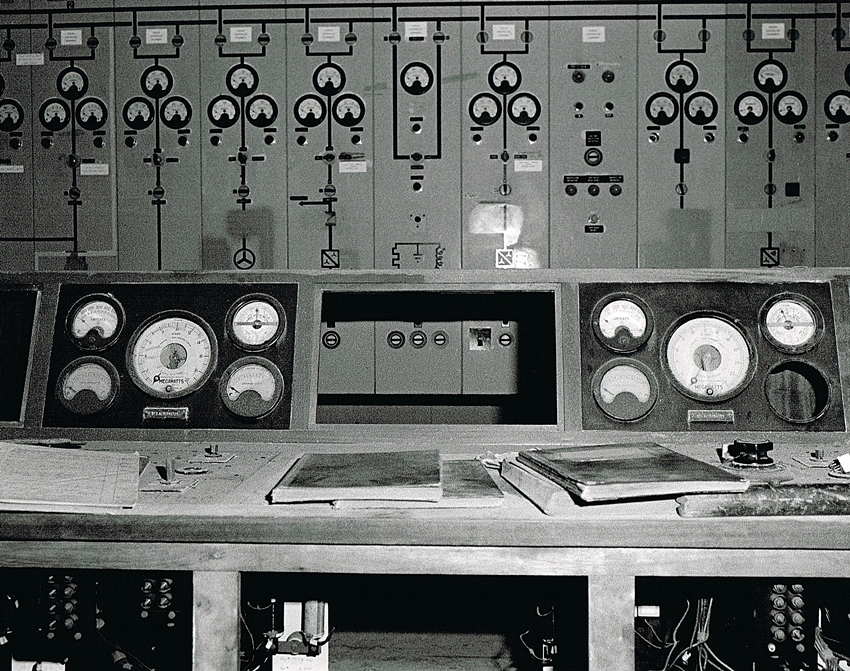

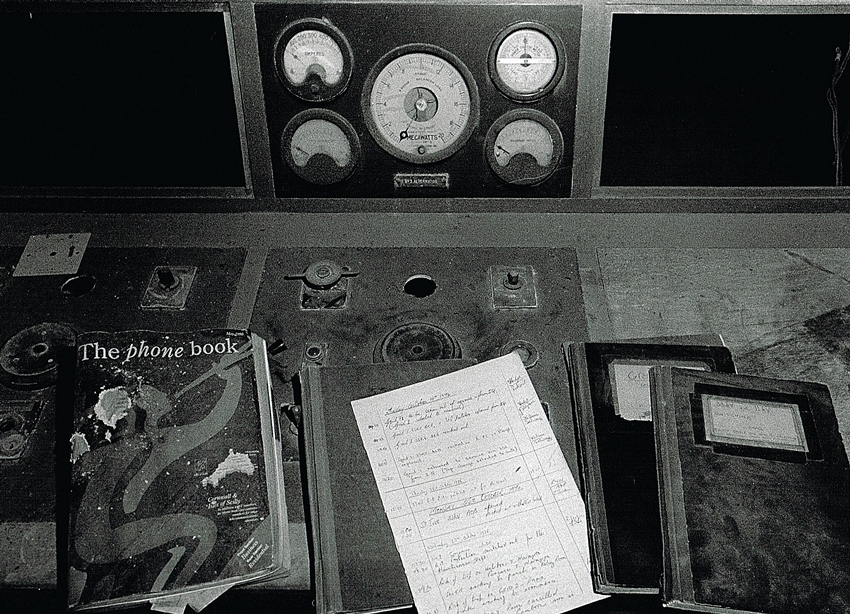

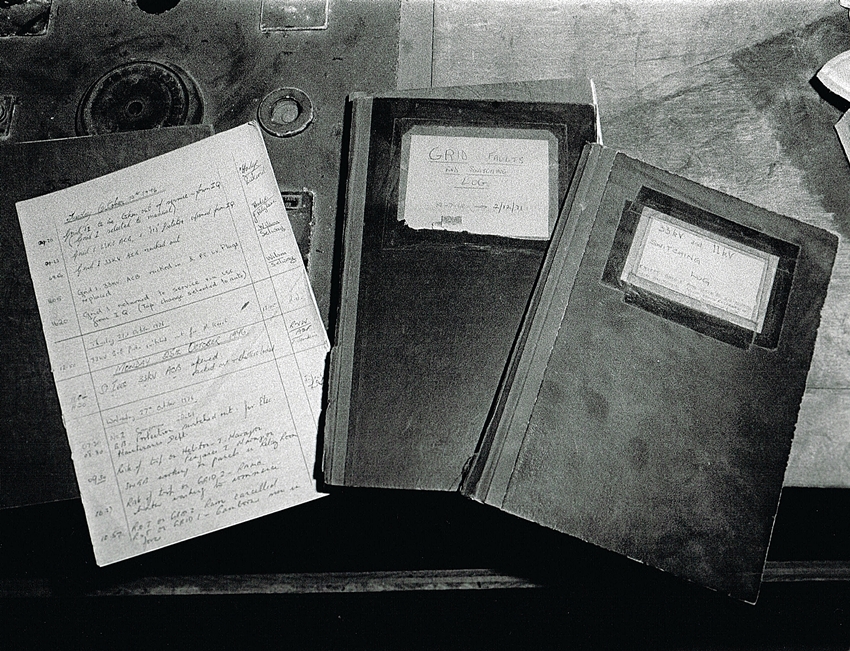

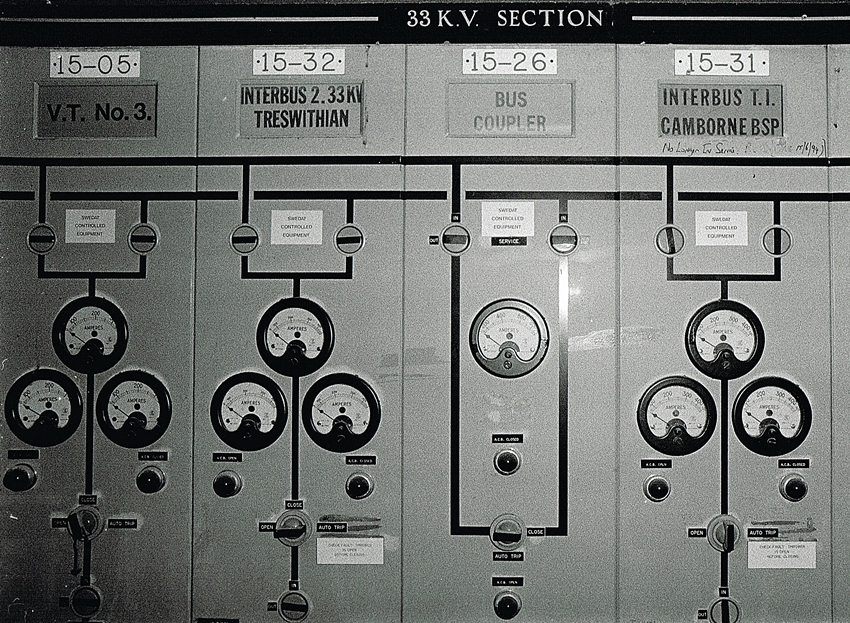

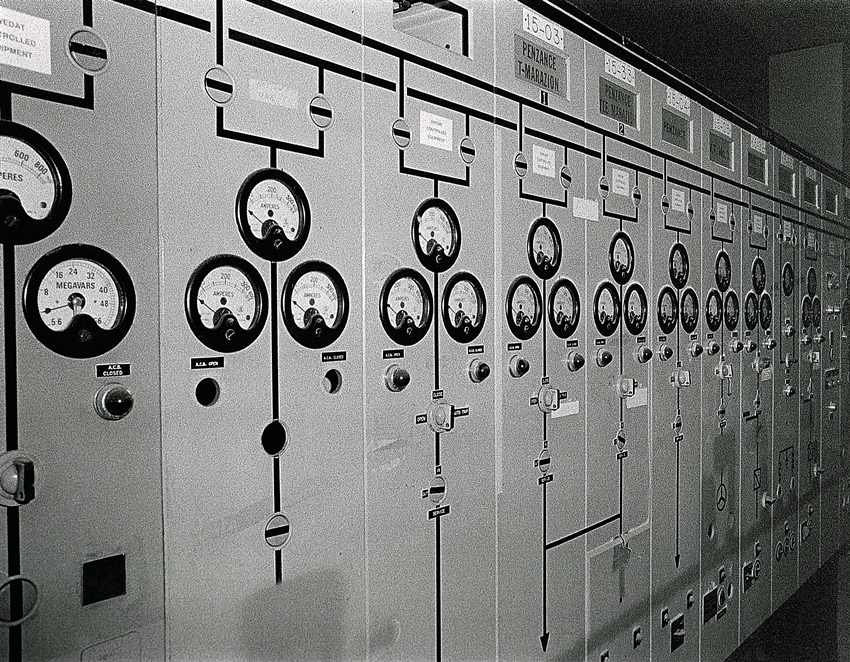

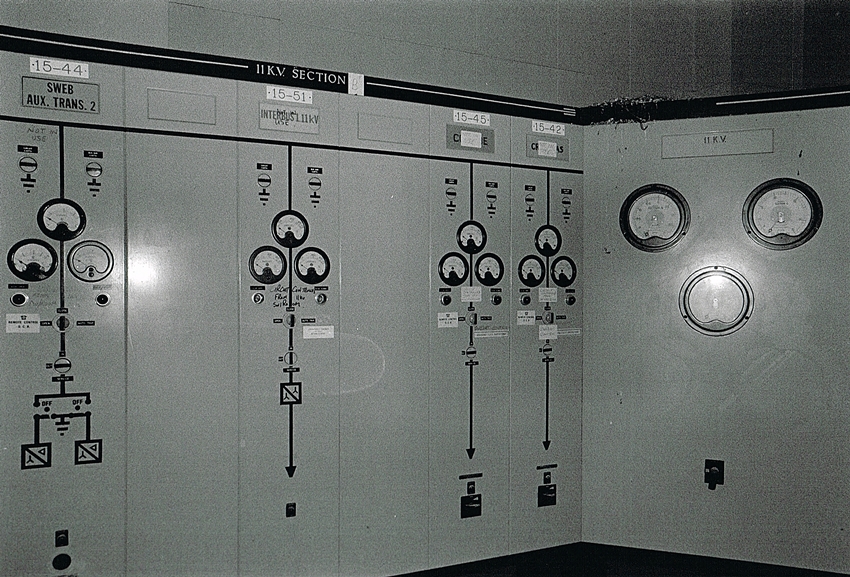

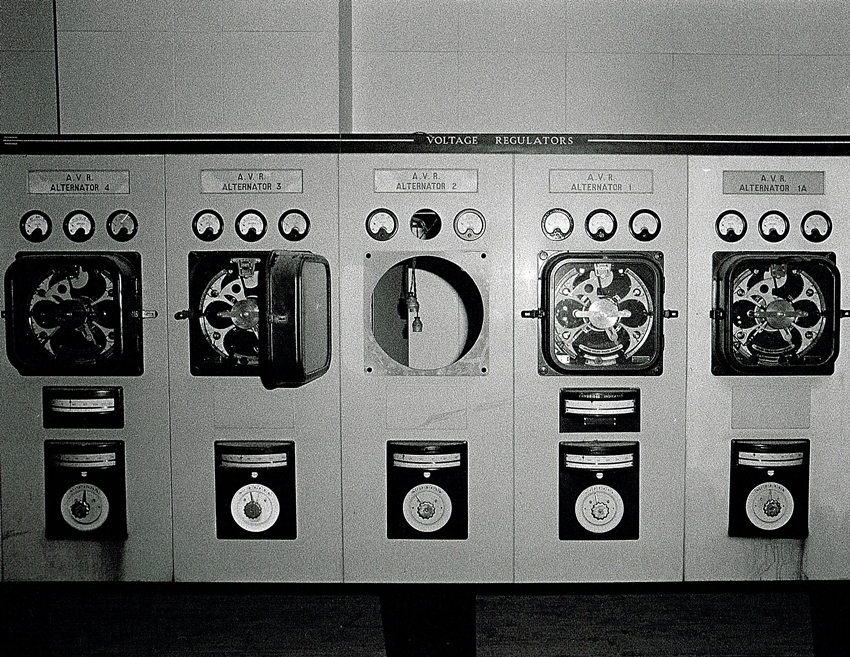

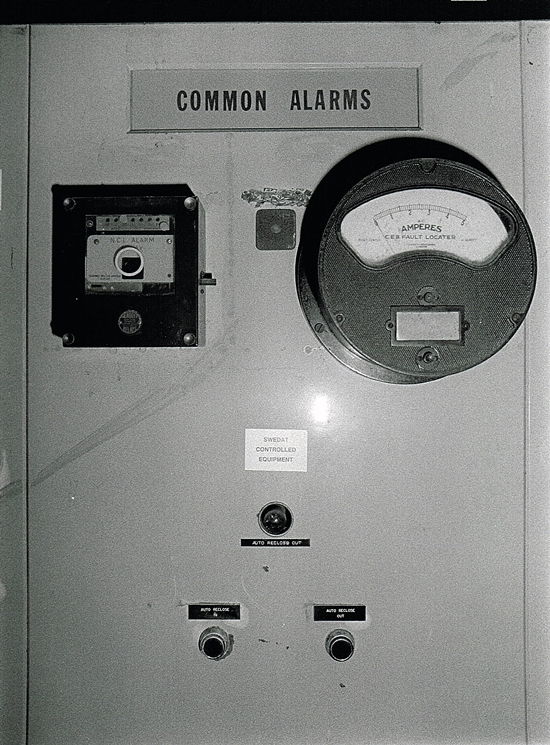

The following images were taken in the main control room of Hayle Power station. It is quite an amazing place, like something out of a Dr Who stage set.

The remaining images were taken in the distribution tunnels underneath the facility. Most of the copper wires had been removed but huge chunks still remained.

A large storage area was at the end of the tunnel, originally this would have been an active part of the power station.

What an amazing trip, the building holds so much history. Although this is off the topic of mining the Power Station supplied power to many of the mines in West Cornwall.

This site is on Private land and should not be entered.