South Crofty Mine Underground 8: I was so lucky to have so had many South Crofty visits. But it’s only looking back now that I realise that I have no pictures of the miners coming off shift. So many times I rode the cage, but I was usually knackered and the cameras had been packed up. However, maybe just once would have been nice. I guess I always thought Cornwall would have a mine, it’s very sad.

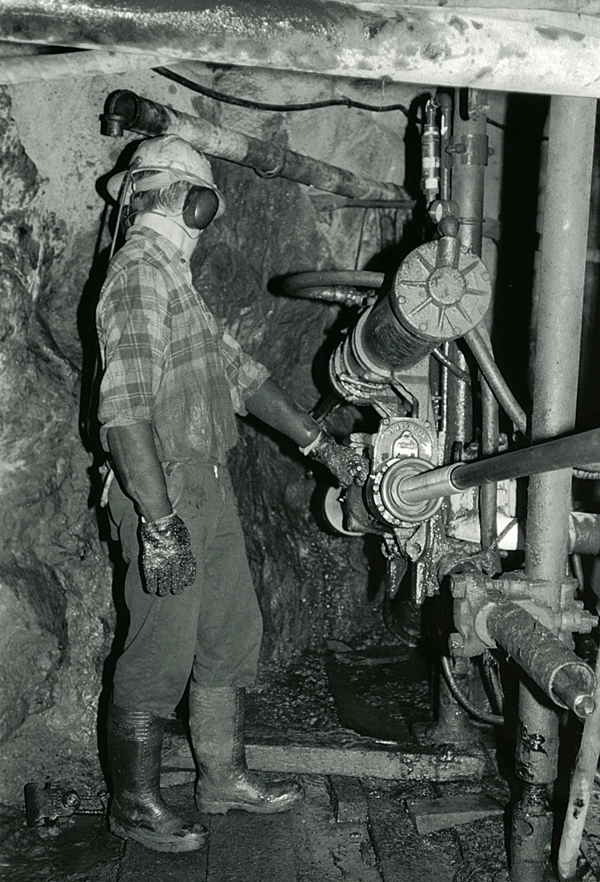

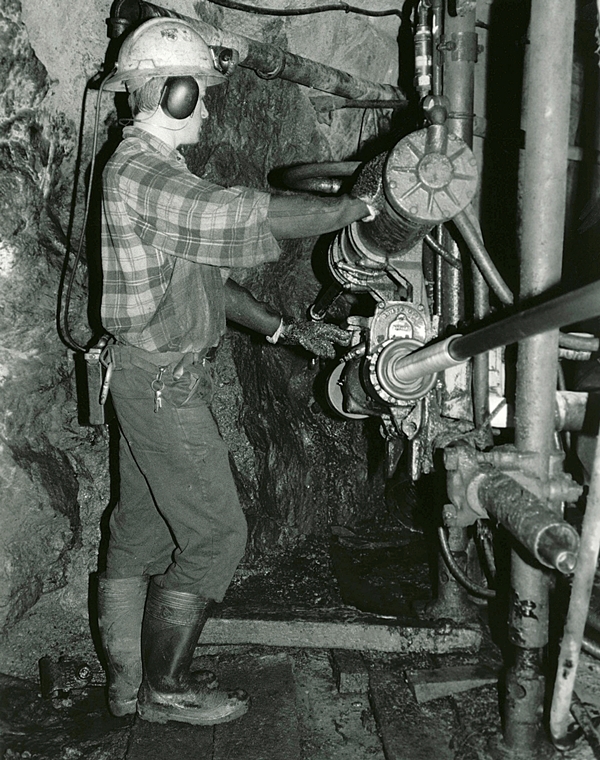

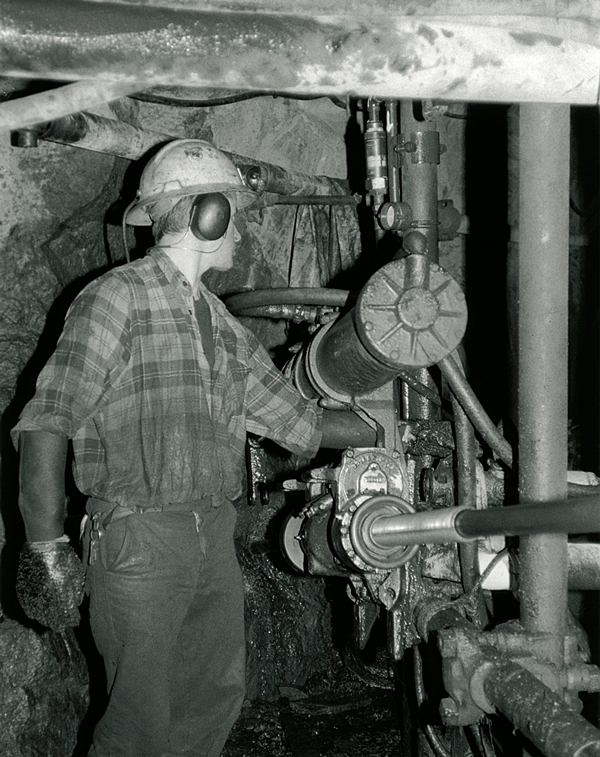

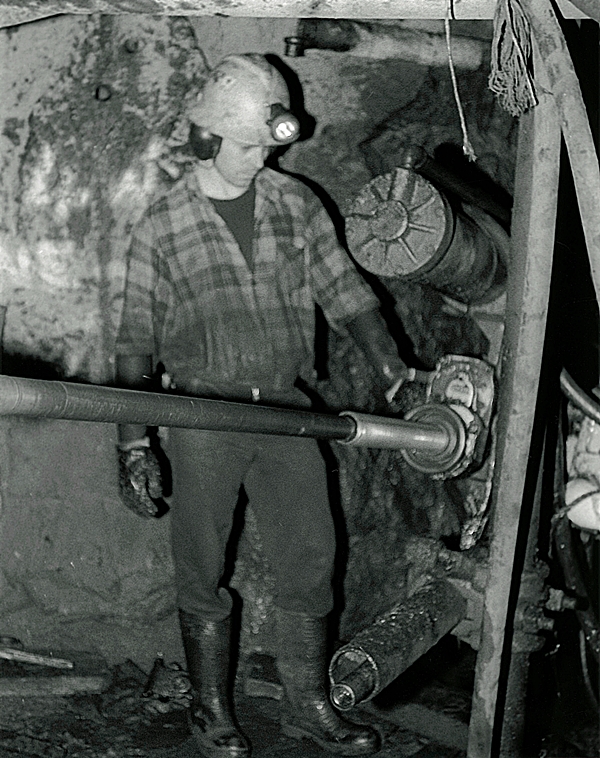

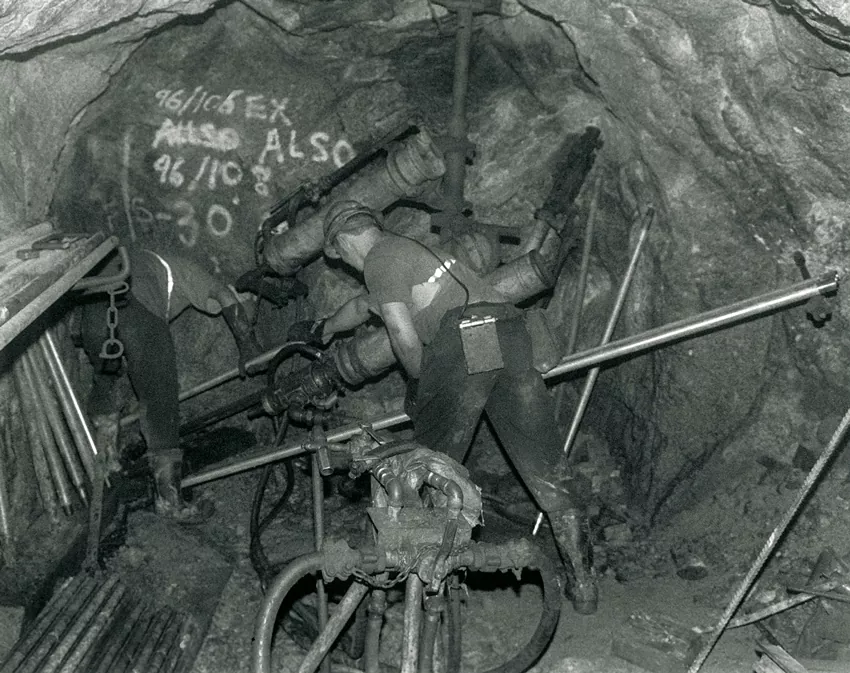

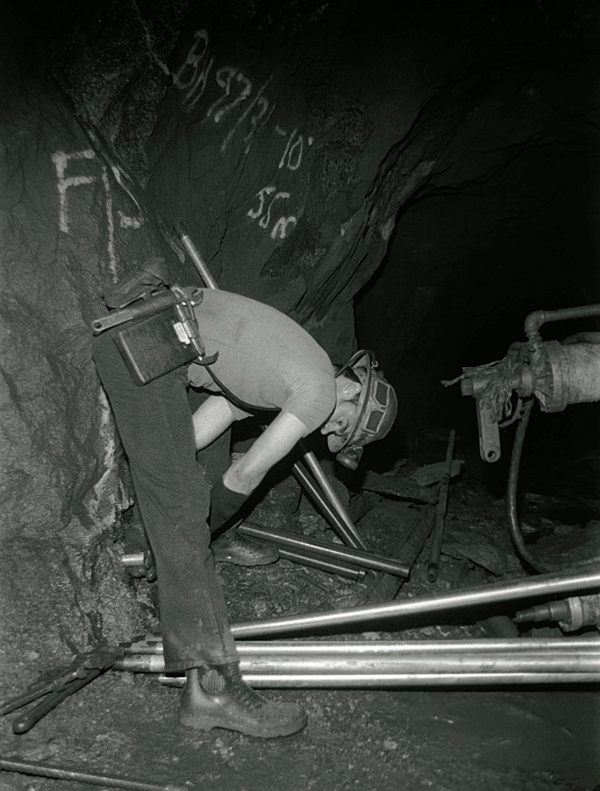

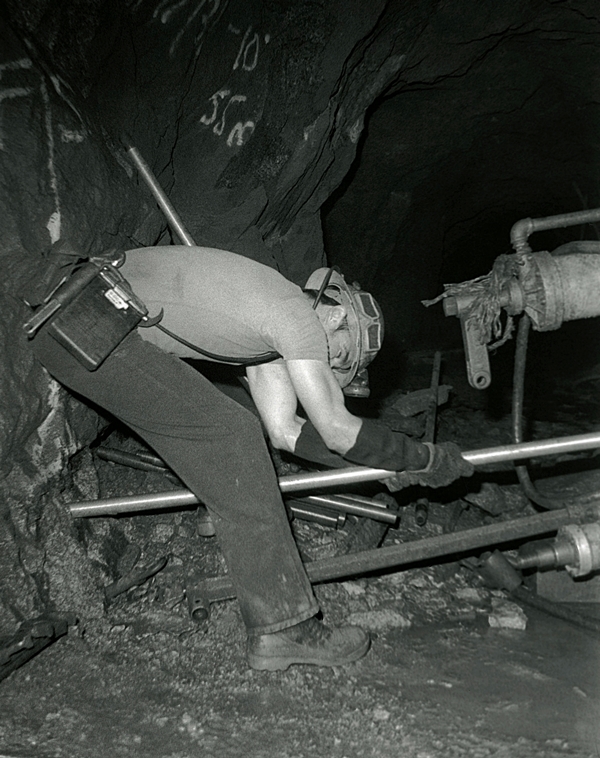

These are the final images of the Diamond Drills and Drillers.

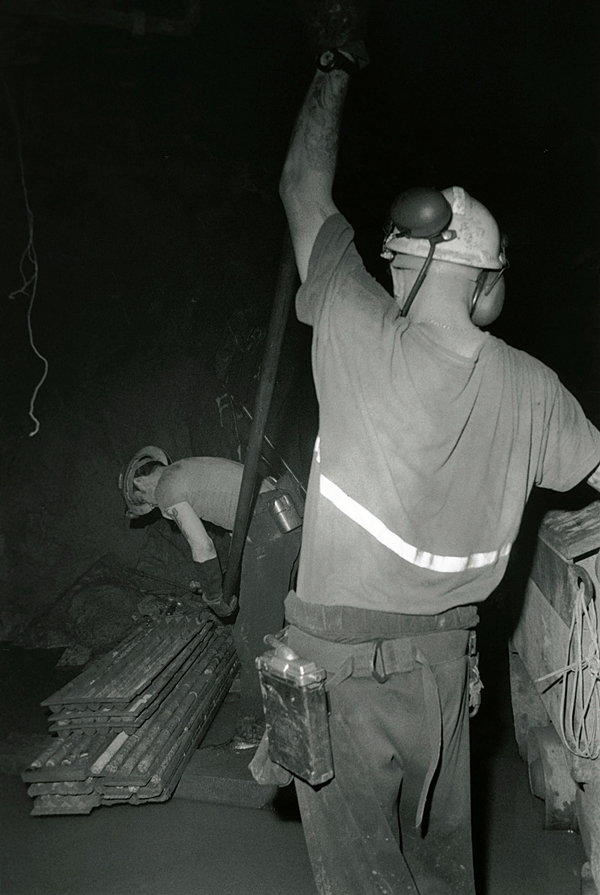

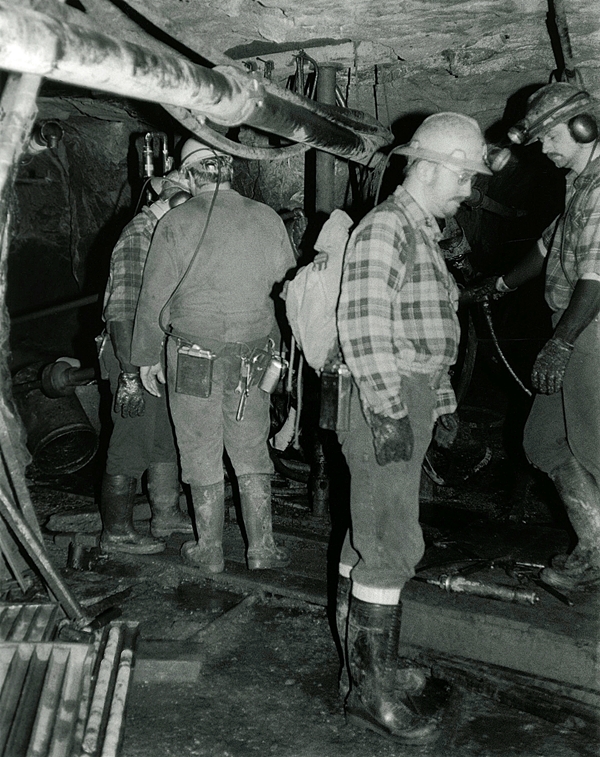

Another drill site with John Usoro, part of the Geologists job was to constantly monitor the drill activity in their areas.

Jonny has kindly written a few lines for me about his work at South Crofty:

I ran a Boyles Bazooka underground coring rig. It was a small access compressed air driven two man drilling rig running TT 46mm drill string and core barrel with a slightly over sized reamer. The spec of the machine was up to 50m over 360 degrees however we ran her up to 130m over any inclination.

The rig was made up of a ram on a rail fixed to the wall with a rock bolt. Then the rig was mounted on a large acro prop to allow the rig to drop down to pull the drill string. This was done manually on shallow holes up to 50m but pulled with a air driven rod handler if a down hole was drilled. The drill was rated at 130 decibels in the open but in a blind end with no vent it could be 200 so we used ear plugs and muffs. Pulling the rods by hand was very strenuous. I remember after about 2 weeks of it hardly being able to drive my car home due to cramps in my arms from the work.

Me and snitcher on 420 level used to drink 5 litres of re hydration solution every shift and still piss brown. The rig was a vast user of compressed air. About 400 cfm which was piped under ground via the shaft in 8′ pipe. The miners in our vicinity used to complain of the massive usage of the bazooka when we went on. They found their air legs on the rock drills used to sag with all the air we used. We used to try and run on the back shift so as not to use all the air but then the trammers winged as we were using their air!

The set up of the rig was vital as you could be in one point in the mine drilling 10 different holes of various angles and length from a single drilling set up. I was most unfortunate to be placed by the great cross course fault on the 420 level for 5 weeks where it was very wet . A kind of Chinese water torture from the water dripping on my hat! We only had a small spot to roll a cigarette from our dripping nose to our dripping helmet brim.

The other thing we did on a Friday was drink. Several of us would meet up and you could always tell crofts men as they would shout at each other in the bar still thinking we had ear plugs in. The response was a clinical eye contact as you still thought you had a head lamp on!!!!

Bloody funny in a night club.

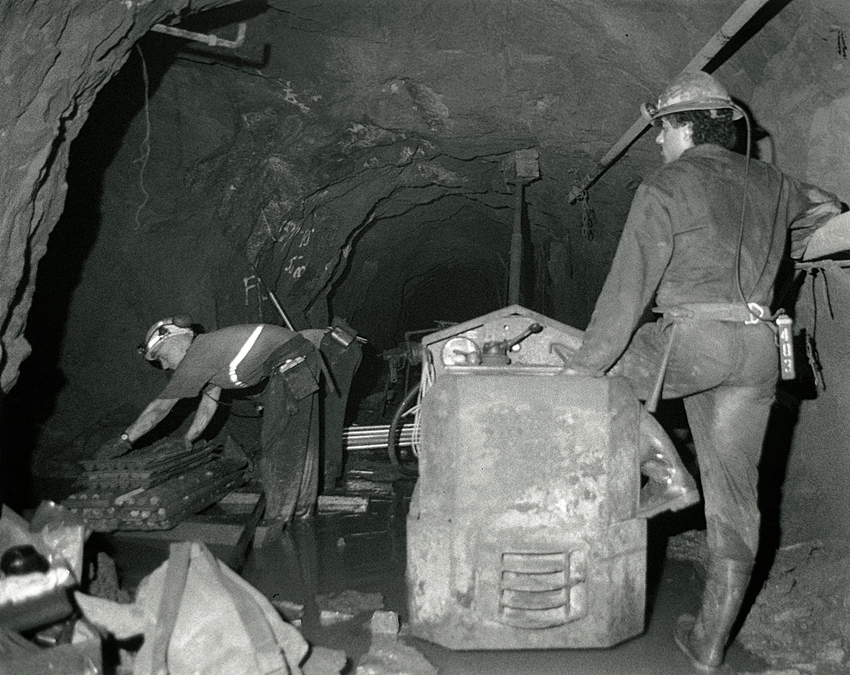

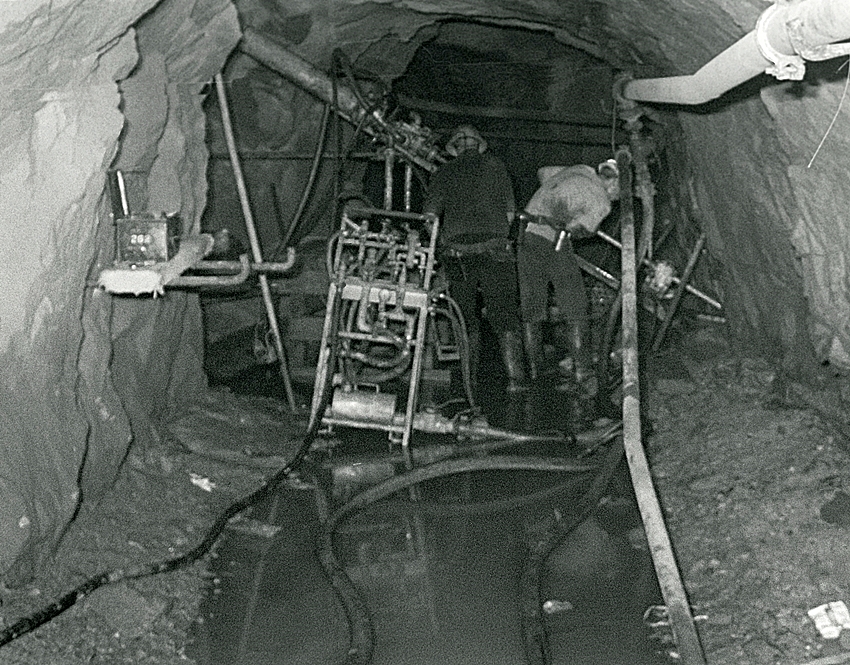

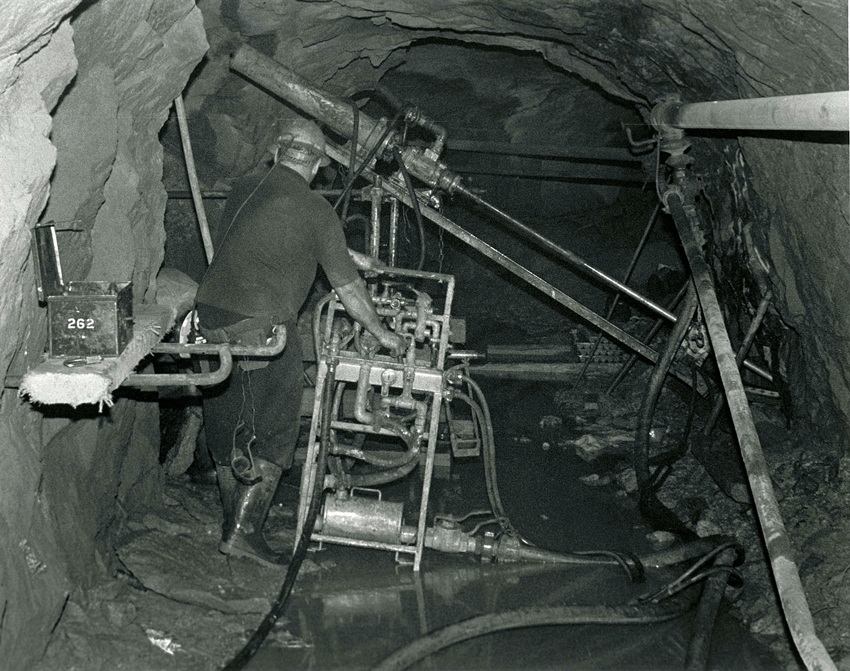

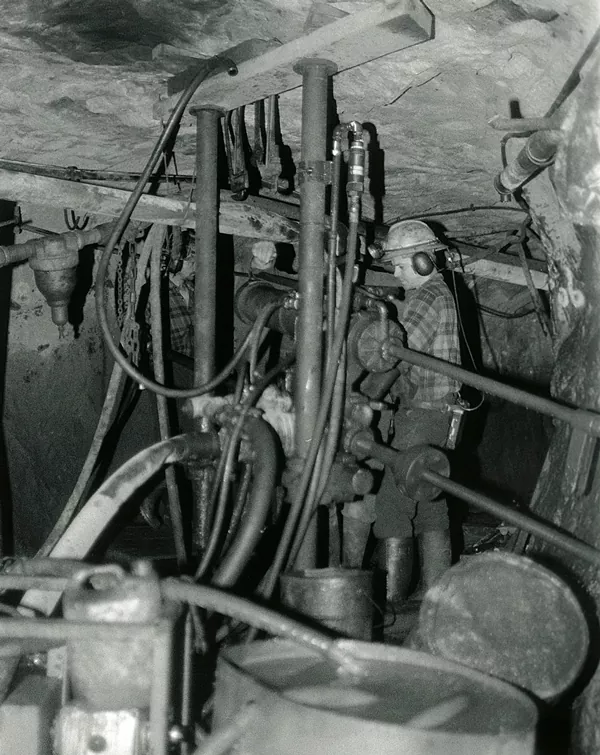

During one of my trips with Nick Le Boutillier we went to the Robinson’s Section on 380 Fathoms. This was one of the biggest Diamond Drilling rigs I had seen underground. The geologists were looking for an extension to the No:9 Lode down to 400 fathoms.

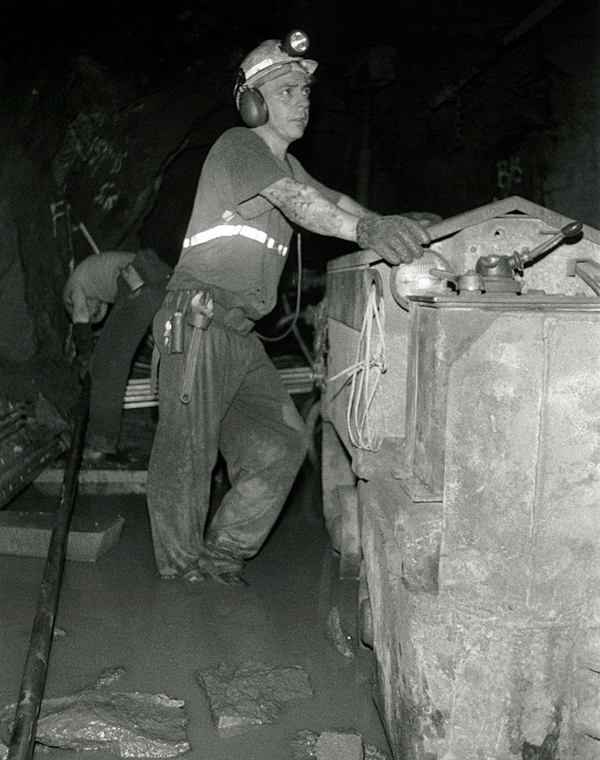

Sadly because the intercepts were weak the drilling was abandoned. The remaining images are all of the same machine at work. I have printed every image I have of the machine as they are unique. The drill was operated by Paul “Winja” Coppinger whom I still know to this day.

Paul (Winja) has kindly put together a few words for this page about Diamond Drilling using the VAG Drill Rig:

Boyles VAG Diamond Drill. This drill was used to drill 46mm wide holes, in order to gather cores in a steel barrel. This was so the Mine Geologists could establish where the Tin veins were and what values they could expect to get when the area was mined.

The drill motor contains plastic veins that are turned by forcing compressed air into them at around 100psi. The motor is lubricated with rock drill oil, these drills are rated to drill up to 290m holes. The core samples are collected in a 3m long barrel where they are then sent to the assay lab for testing for tin content.

During use these machines are extremely noisy. The volume is not too dissimilar to that of jet engine at take off, and it wasn’t uncommon to find that your teeth would chatter together when running at full power. On one occasion the water swivel bearing seized up and my hand was caught in the armoured water hose. I was pulled off the ground and only just managed to free my hand. My glove remained caught in the hose, the drill ripped the top off the water pump and hurled it around the site at frightening speed. I was so lucky to escape with just a broken bone in my hand.

So, hence forth the VAG became affectionately known as The Widow Maker.

Winja. Diamond Driller South Crofty Mine 1985-1998