Cornish Mining Industries, whilst the mining industry supplied the valuable metals to the smelter the mines themselves needed supporting. Consequently huge engines were developed and constructed in the foundry’s in Cornwall to drain the mines.

Whilst other factories grew; Explosives, fuse works, rope works, transport, rockdrills, and air compressors to name but a few. Many of the related Industries that operated made huge profits from the mining.

The majority of the images on this page were taken in the 1990’s. However one of my big regrets is I have no images of the Holman Factories in Camborne. These were by all accounts lovely buildings, also one of the major Mining Industries in the area.

The Perran Foundry was first established by the Fox Family of Falmouth. The site was open during the years from 1791 to 1879. The closure was brought about by a decline in the Cornish Mining industry. At its height from the 1820’s to the 1860’s there were 400 men employed in making pumping engines which were exported all over the world.

The Harveys of Hayle Foundry worked from 1779 to 1903, making many mine pumping engines and ships.

There are more images on the Hayle Gallery Page

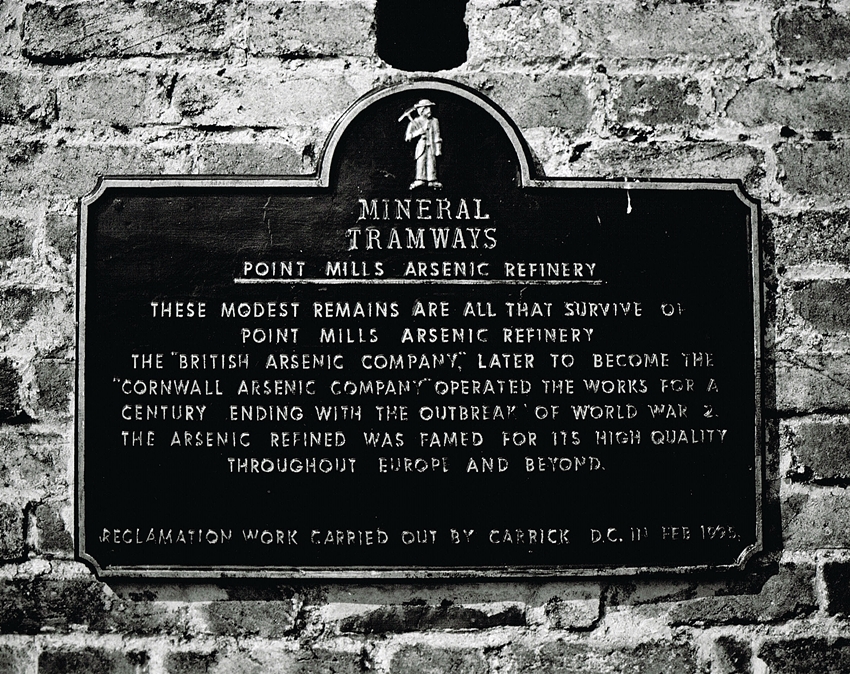

One of the by-products of the Cornish Mining Industries was Arsenic. Many mines would process their own, but there were still many refineries were operating in Cornwall. Arsenic had many uses at the time; used in Lancashire to dye Cotton, pigments and colouring for wallpapers. It was also shipped abroad for use in pest control and glass making.

The remains of Point Mills works at Bissoe in the Carnon Valley. It was operated by the British Arsenic Company which ran the works for a century up to the outbreak of World War 2.

Transport in the boom times of Cornish Mining was always a problem for the mine owners who needed to get the ore out to the ports and to get coal and materials to the mines. One of the solutions was the Portreath Tramroad, it was the first railway laid in Cornwall, owned by the Williams family and the Foxes of Falmouth.

At Portreath work started in 1809, by 1819 the 6 miles of line was in use. It initially served North Downs Mine, but was extended to Treskerby Mine along with a storage yard at Croftyhandy. The track was made from three foot lengths of “L” shaped cast iron, mounted on Granite setts with a gauge of about three foot.

The wagons were horse drawn and the wheels ran inside the flange of the rails. Eventually the line closed in the 1870’s. The tram is now a path that joins on to other Mine trails and it’s possible to walk from Portreath to Devoran. a great tour of the mining districts I should know as I walked it several times for the Bob Acton books on the subject.

Many recovery plants or “Stream Works” worked in Cornwall to reclaim Tin from the waste from mines processing floors. As a result The Red River was named for its red colour due to the minerals it carried had nearly 30 plants working it.

The images below were taken at The Brea Plant overlooking Tuckingmill.

The Tolgus Tin Streaming Mill was the last to work in Cornwall, it closed in the late 1980’s following the crash in Tin prices, today it’s a working museum. Below is an image of a Round Frame used to collect fine particles of Tin. So, I chanced my arm and took the photo on a single flash with a 17mm lens, I was rather surprised at how well it came out.

For more information about Tolgus Tin follow this link: Tolgus Tin

The safety fuse was invented in 1831 by an English merchant named William Bickford, in Tuckingmill, near Camborne. He subsequently developed a reliable and safe way of firing powder underground where so many miners had been killed or maimed by blasting accidents.

For more images of Bickford’s Fuse works follow this link: Bickford’s Fuse Works

Many explosive factories were running in Cornwall supplying the mines with powder. Cligga Head works were constructed during 1889 by the “British and Colonial Explosive Company”. This was later purchased by Nobel Explosives in 1892.

For more images of Parkandillick follow this link: Parkandillick Engine House