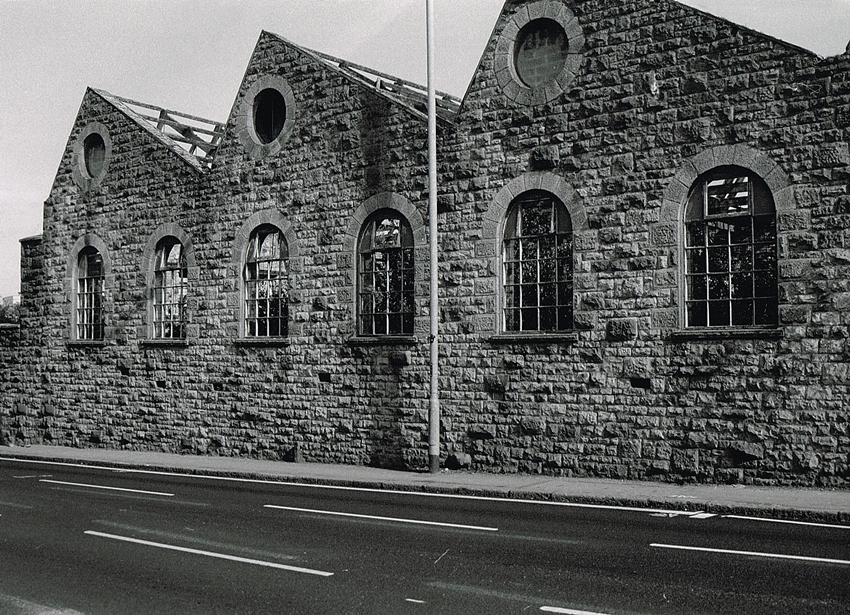

Bickfords Fuse Works: The remains of this important site can be seen in Tuckingmill along the side of the A3047 leading into Camborne.

For many years the Cornish Miners in the late 18th and early 19th centuries faced the prospect of accidental injury from the gunpowder they used to blast the drilled holes in the mines. Therefore care had to be taken as the gunpowder was easy to ignite when exposed to sparks, heat, or flames.

The miners would use hand turned drills to drill several holes into the rock face at the end of a drive, each hole would then be filled with gunpowder. A pointed rod called a “needle” was placed in the charged hole, soft clay was then moulded around this rod and tamped tight using a wooden rod. Because it was dangerous to use metal as it could produce sparks. On removal a fuse would be inserted into the hole, lit and the charge would blow.

It all sounds very simple but accidents and injuries were a constant threat to the Cornish Miner. The main issue was igniting the hole itself, the fuses used at this time were straws or quills filled with black powder. These were notoriously unreliable and dangerous to use even to the experienced man.

The early fuses would burn irregularly thus making it difficult to estimate the time to the blast. These were easily damaged either in transit or when the hole was being prepared. If moisture was present the fuse would smoulder rather than burn leading the miner to believe the charge would not go off. Often the explosion was only delayed and because of this many miners were killed or injured in their haste to return to the work face.

The problem was solved in 1831 by an English merchant named William Bickford, a Methodist, originally from Ashburton in Devon. In Tuckingmill, he developed a reliable and safe way of firing the powder in the primed holes.

Having visited a friend who was a ropemaker he believed the same methods of winding cords to produce a rope could be applied to creating a fuse. With help from a working miner called Thomas Davey and his son-in-law George Smith, Bickford successfully invented a device which would produce the patent “Safety Fuze”.

The machine was designed to cover a tube of gunpowder with jute yarn spun in opposite directions; the resulting product was then varnished in tar so it was waterproof. The patent was awarded on 6th September 1831: No. 6159 “Safety Fuze for Igniting Gunpowder used in Blasting Rocks, Etc”.

The final product was a waterproof fuse that burnt in a predicted rate of 30 seconds a foot so an accurate burn time was easily calculated by the length of the fuse. It will never be known how many lives this invention saved, the face of mining had been changed forever.

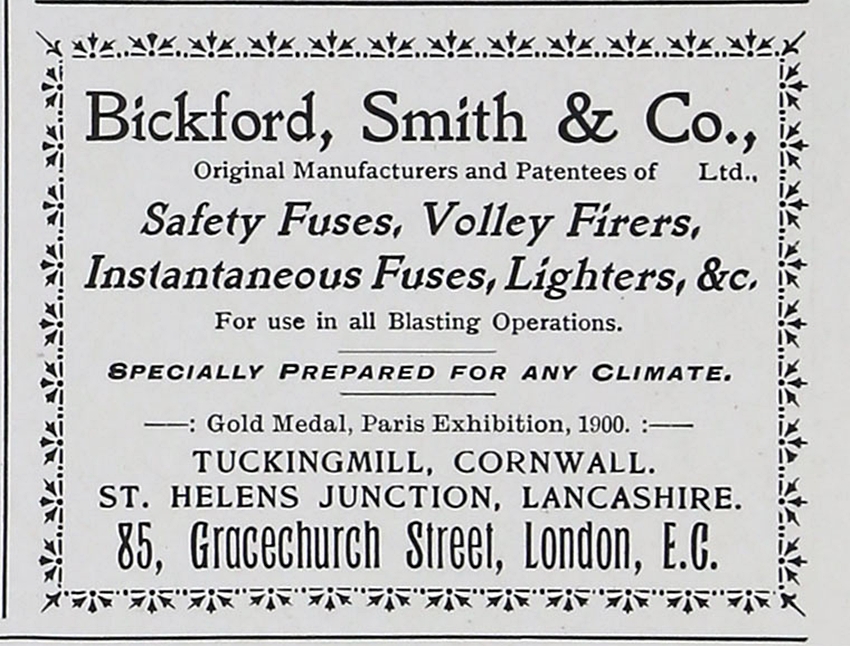

The present day remains of the factory were purchased from Tuckingmill Foundry in 1888, prior to this the fuse was produced over the road. The company was taken over by Nobel Industries in 1921, safety fuse continued to be made on the site until July 1961.

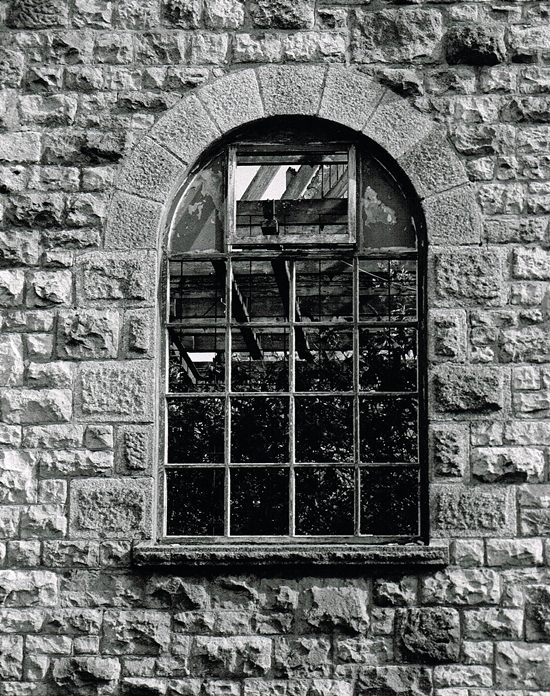

There is a commemorative plaque set in the wall as a lasting memory to William Bickford’s invention. The images on this page were taken in early 2013.

On this occasion the gate to the rear of the workshops was open. I wandered in and was lucky enough to have a good look around the Bickfords Fuse Works site. Entry into the buildings was unwise due to their dangerous condition.

As far as I am aware the site is destined for redevelopment. I believe the frontage of the factory is preserved and needs to be incorporated into any new building.