South Crofty Mine Underground 9: To the South Crofty Miners it was more than a job. They took frequent wage cuts and worked longer hours to keep the mine working. It was a way of life to them and the living life blood of Cornwall.

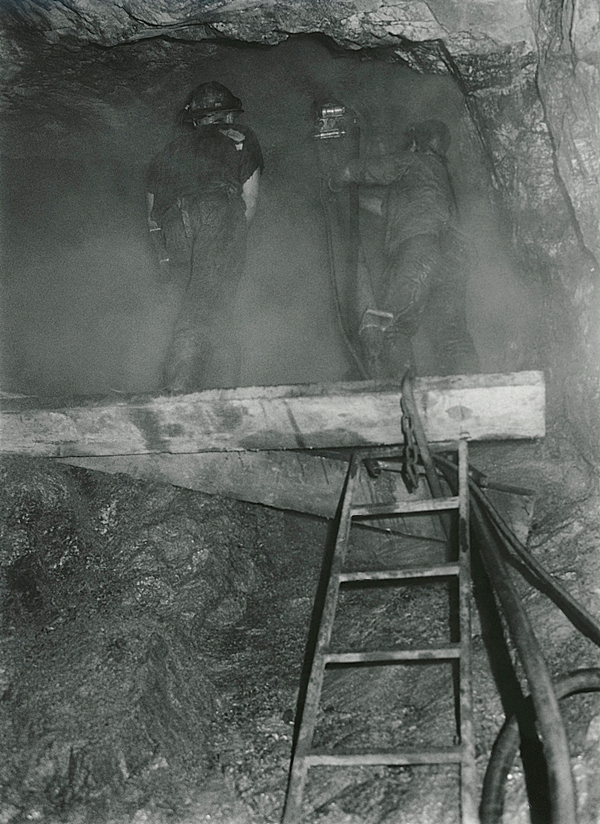

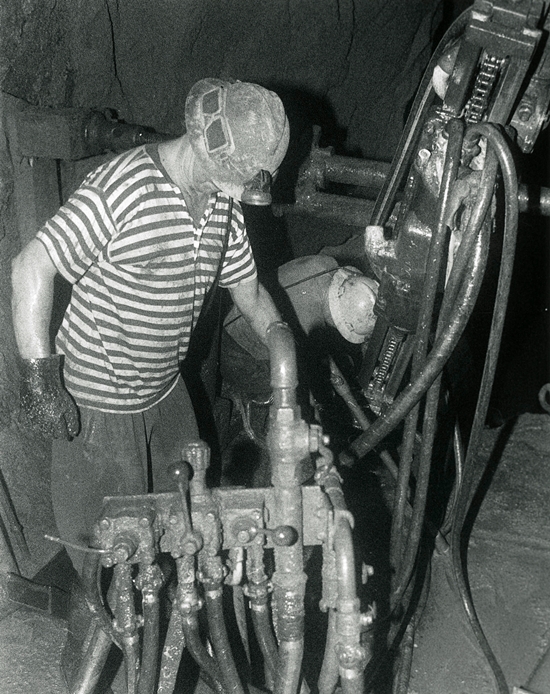

This page is the first showing the method of ore production from South Crofty Mine. This was known as “Stoping”, the empty area once cleared of ore are known as “Stopes”. These first images on this page show a mining method called “Shrink Stoping”.

The late Dr Nick Le Boutillier wrote some information about this technique for this page.

Shrinkage stoping, more correctly, overhand shrinkage stoping is a mining method that was used extensively at South Crofty. Particularly with the advent of compressed air drills in the 20th Century. It is a technique ideally suited for steep-dipping narrow lodes in structurally competent host rocks, such as found at South Crofty.

Short raises within a pre-determined panel, bounded by level to level raises, were joined laterally to form an inter level. Box-hole (Cousin Jack) chutes were built into the raises to transfer broken ore (dirt) out of the stope. The bounding raises were panelled with timber, progressively upwards, to hold in the broken dirt and to maintain a ladderway into the stope from above or below. The miners, working from the inter drilled into the roof (back), firing the lode in lifts.

After each blast the miners would stand on the broken rock of the previous day to reach the back and drill over the next lift. Because broken rock takes up some extra 30-40% volume, the swell had to be drawn off. This was done via the chutes, to shrink the broken rock back to allow access.

The retention of broken rock in the stope added continuous support to the stope wall. This also formed a stable platform for the miners to work from. Shrink stoping was/is a very efficient technique. It allowed the miners to follow a lode very exactly, maximizing ore recovery, while taking a minimum of waste rock.

Lodes are often visualised as planar features. However in reality they flex and undulate along strike as well as down and up dip. A good crew is able to follow the lode contacts very closely and minimise dilution. The only real disadvantage of the technique is that relatively little ore is produced daily. Only the swell tonnage is taken until the stope is complete. At this point the whole stope panel can be drawn out and sent to the crusher.

Later development at South Crofty moved away from boxholes and inters, to draw points driven from a parallel (waste) drive. Although this required much extra development, it removed the need for timber chutes and allowed the use of rocker shovels and Cavo’s to fill the loco trains more quickly and efficiently. Also this allowed better access.

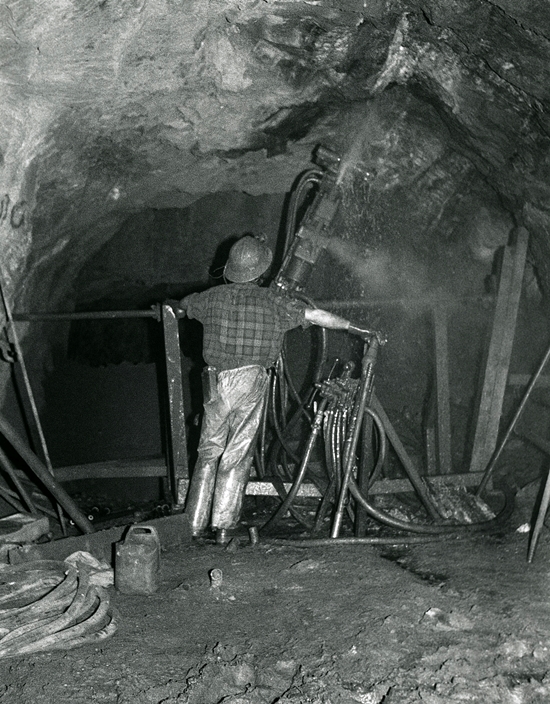

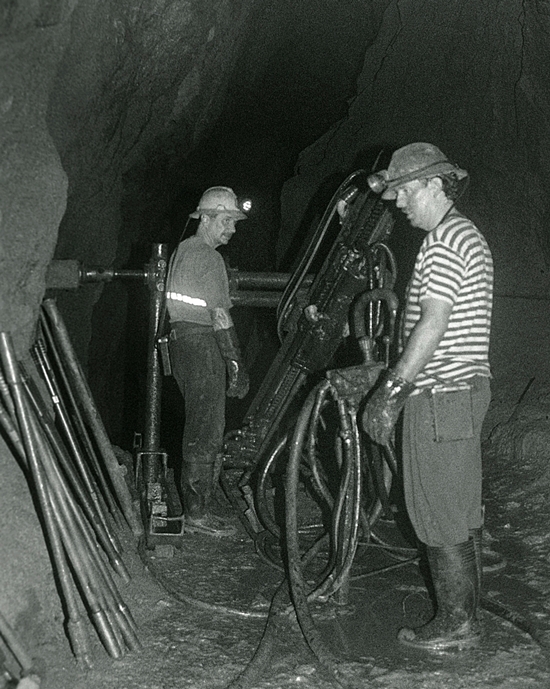

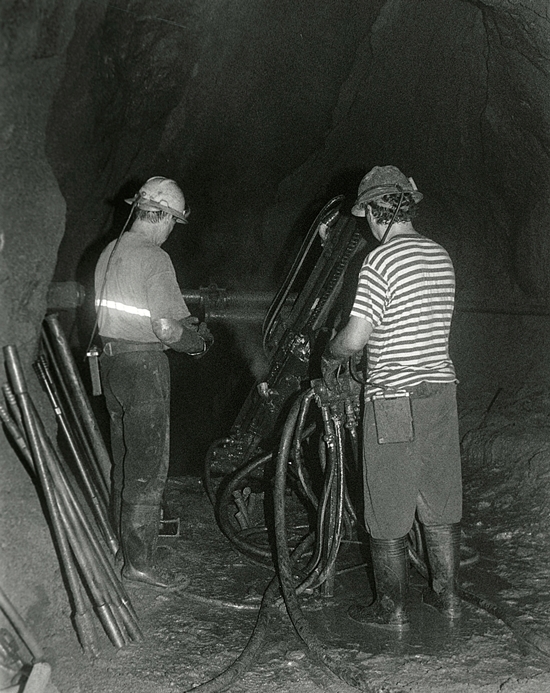

This rest of this page continues the set of images showing the main method of ore production from South Crofty Mine. This was known as,”Longhole Stoping”, once again Dr Nick Le Boutillier has written some information on this method.

Longhole stoping was developed at South Crofty from the 1970’s as a method of rapid extraction. Sublevels were mined from the panel bounding raises (usually two between main levels).

Mapping of the lode in these sublevels and raises was the basis for the development of blast rings, every metre along the sublevels. These blast rings were plans for radiating rings of holes to capture as much of the lode as possible and were designed to take out the entire panel in two major lifts.

Starting from a raise on the lower sublevel, rings would be drilled away from the raise and were often fired in groups of up to five although sometimes singly. The rings would break (utilising the open spaces of the raise and lower main level) and the broken rock fall towards the draw points. Extraction of the broken rock could be undertaken immediately and no dirt had to be retained to allow access.

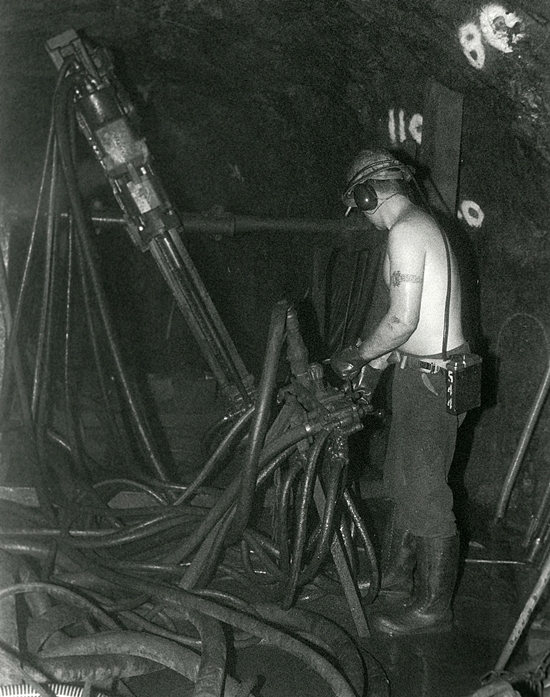

The miner, working his longhole drill rig was able to work safely within the sublevel (with access via the second raise). This was far enough from the open stope to keep his workplace safe and stable. In this way panels work fired in a sequential manner, and once the lower lift was complete. The miner would then move to the upper sublevel and repeated the exercise.

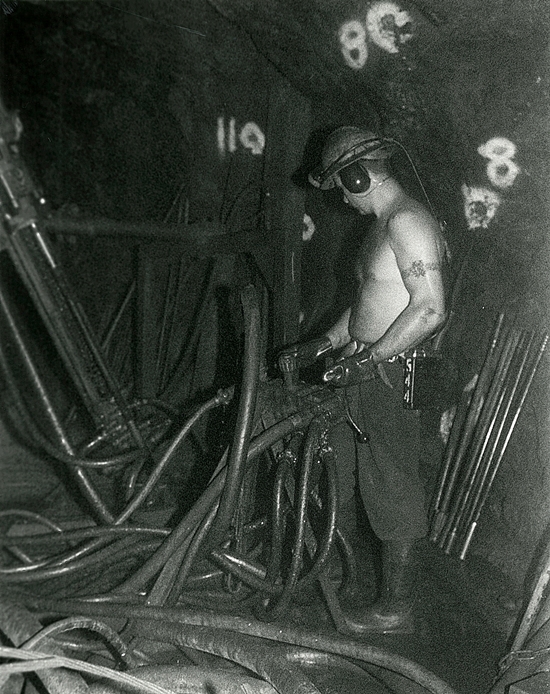

Longhole stoping allowed rapid, continuous supply of ore on a daily basis. Panels could be worked far more quickly than by shrink stoping. It was also ideally suited to larger (wider) lodes, up to ten metres, or more, across. These would have been much less stable in a shrink stope environment.

The disadvantages of the technique were that it was incapable of flexibility – patterns from ring to ring were only able to vary by around 20cm. So if a lode was rolling or flexing, the pattern could not follow the lode exactly like a shrink stopper could, meaning invariably that some waste was taken while some ore was left behind. This meant ore dilution had to be taken into account.

Also the blasting of large rings in unsupported stopes often shook the stope walls so badly that they could partially collapse – leading to further dilution. After some significant dilution events, a process of bolting the the stope walls prior to firing was introduced. However this added significant cash and time costs and had varying success.

Longhole stoping was by far the most common mining method at South Crofty in the 1990’s. This delivered a high tonnage on a daily basis. Also shrink stoping was employed on a number of lodes. This had the advantage of providing high quality, high-grade, dirt in smaller volumes.

Another day and another Long Hole Drill site. The miner in the final set of images on this page is Geoff Tonkin. The negatives were very dense and were very difficult to print, the results were worth the effort.