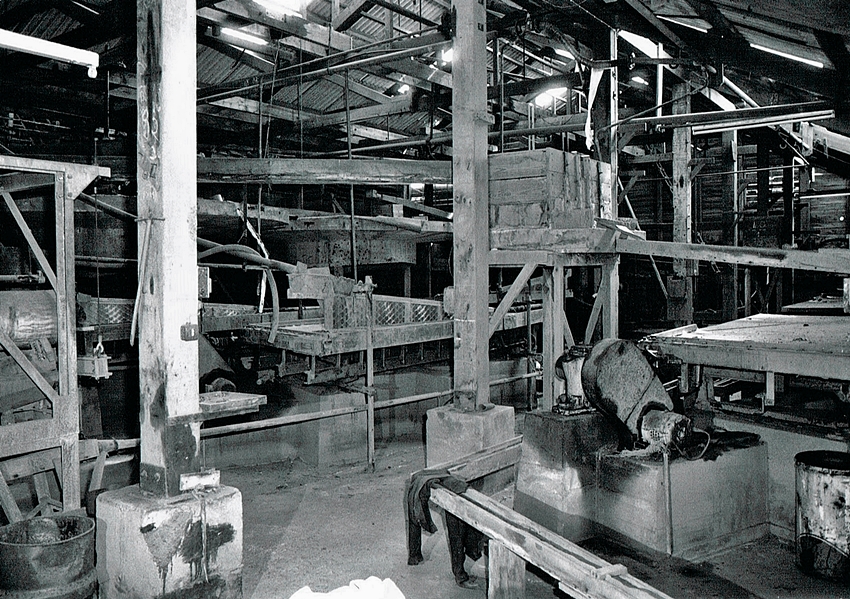

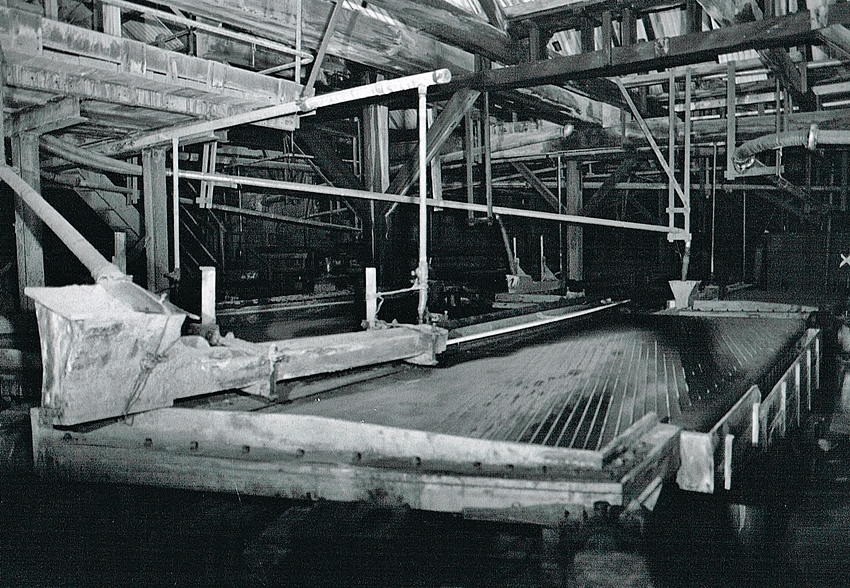

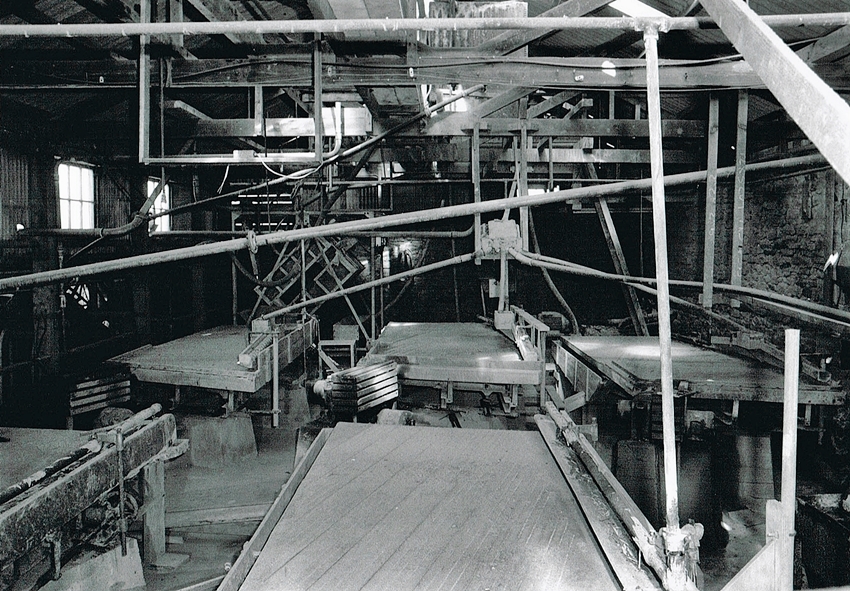

Geevor Tin Mine Gallery 10: This is the final page of the Galleries taken during the early 1990’s before the site was properly opened up. All the images on this page were taken in “Wembley”. This was the Slimes Plant where the final recovery process took place. Once again Bob Orchard has supplied much of the information.

As yet this area is not open to the public.

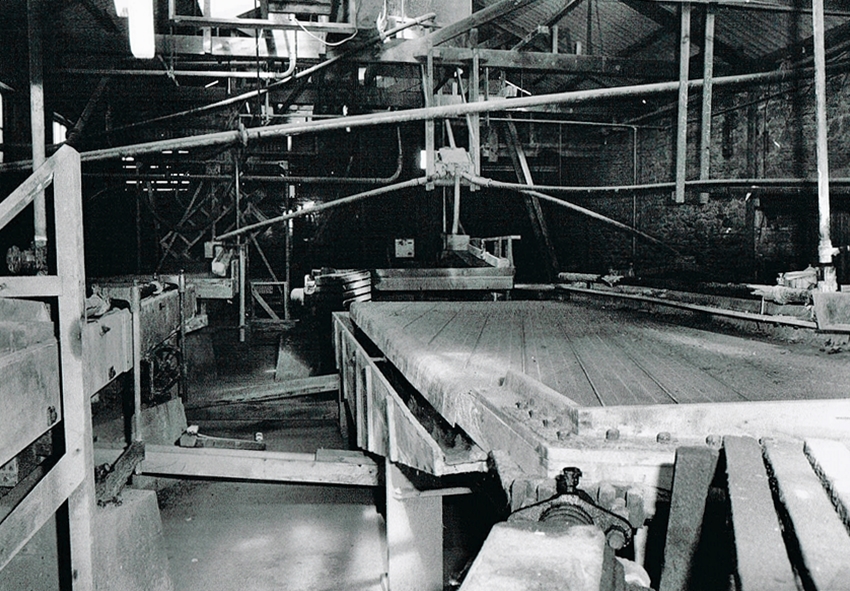

“Slimes plant” referred to locally as “Wembley”. This is where the very fine tin ore was processed, in a more modern mine mill this would be done by “froth flotation”. The slimes plant is where the elusive last few % are recovered. But it is a game of diminishing returns.

Note that the scrap men have cut all the cables from the metal clad switched on the far wall. At bottom right is a pole mounted 440 volt to 110 volt centre taped transformer. Center tapped means that line to line the voltage is 110 volt and either line to earth the voltage is only 55 volt.

Back in the 60’s the mill was lit with 110 volt clear light bulbs. These were also often tucked inside the vents of large open frame Lancashire Dynamo & Crypto (LDC) motors to keep them warm dry in periods of foggy misty weather. Not unusual for Pendeen. As a student from Cornwall Tech in the mid 60’s part of my work was the 110 Volt lighting.

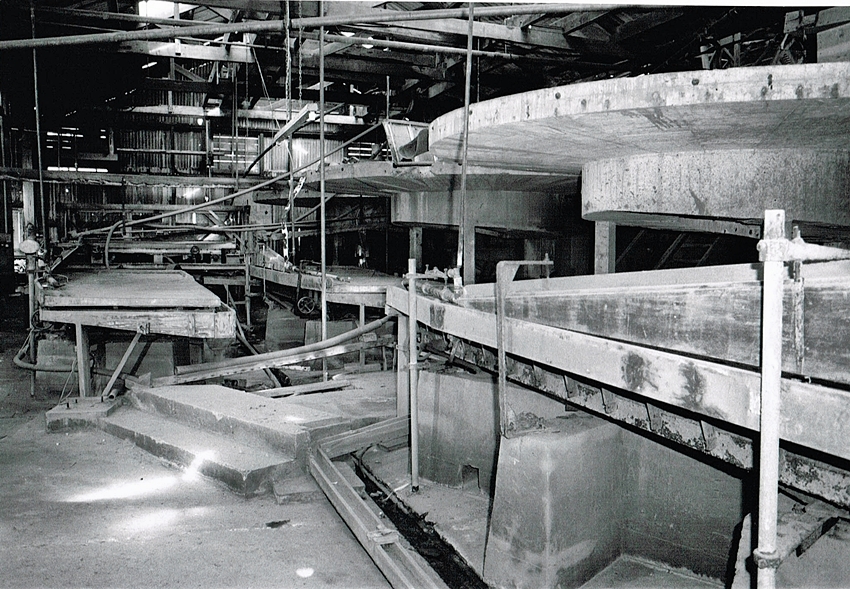

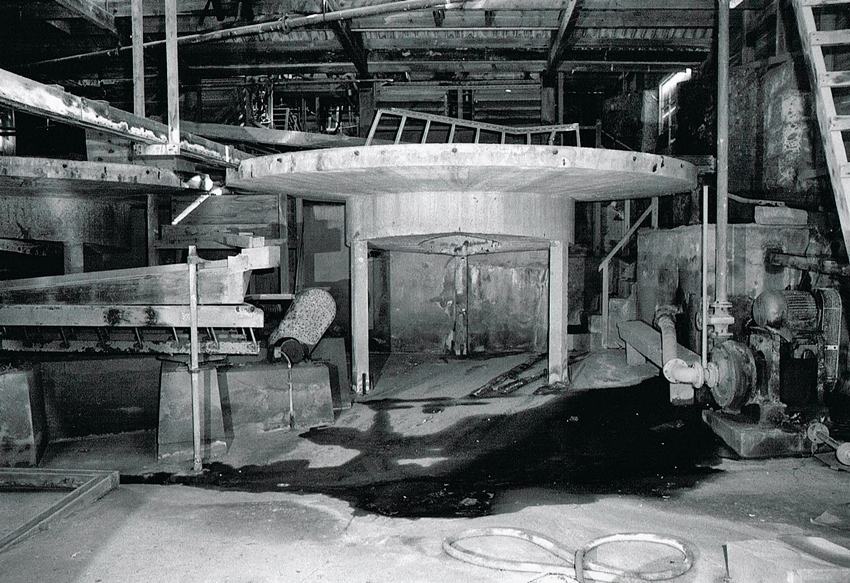

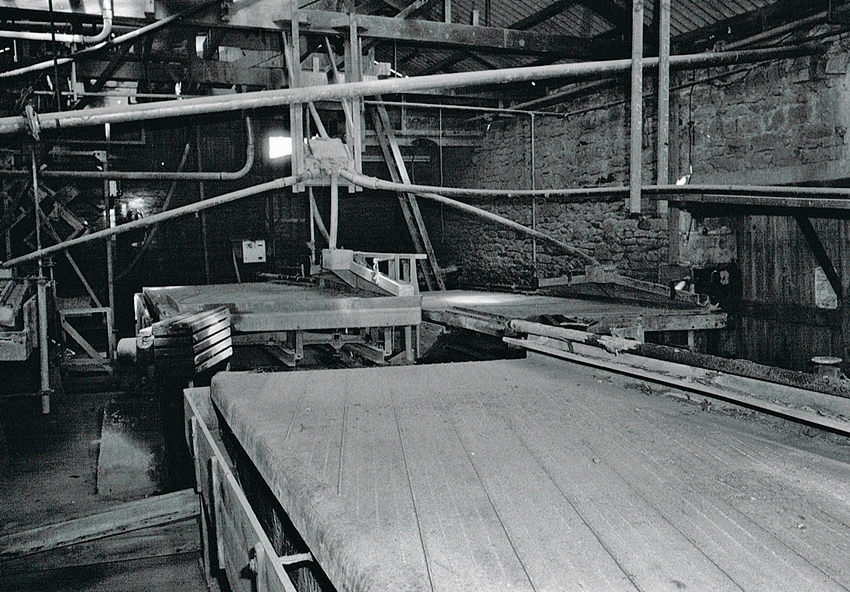

Basically the same principle as the traditional Cornish timber round frame. But the concrete round frames have a stationary deck revolving feed, middling’s,concentrate and tailings launders.

It would be a great (also relatively easy) project to get at least one of these up and running. For which I would volunteer my services.

But just a little note on Holman slimes tables. Firstly, the direction of rotation of the vibrator is the reverse for that of a sand table. Secondly the deck of the table has very gentle riffles compared to a sand table deck. Sometimes the riffles are very low profile strips of copper on top of the linoleum.

But other times the riffles are under the linoleum, giving a very gentle action. The old mill & slimes plant were a three dimensional jigsaw of launders & pipes from all directions.

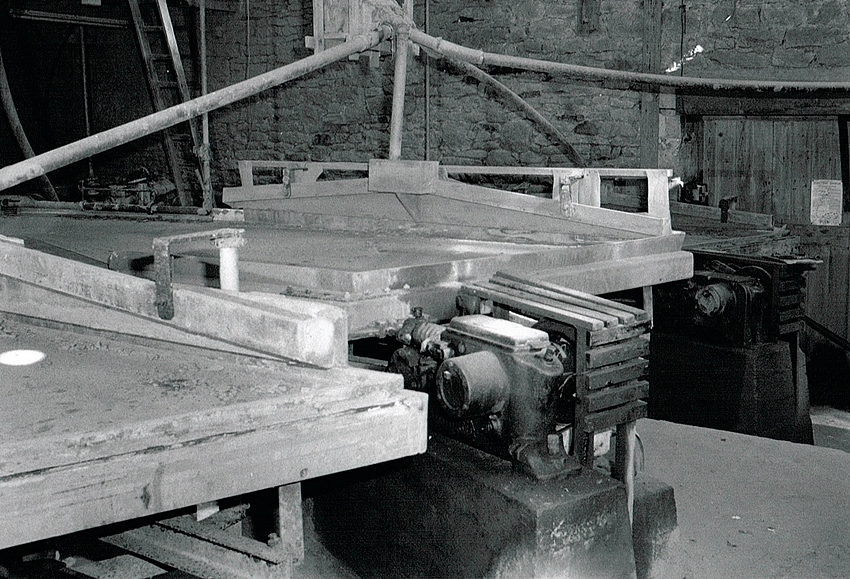

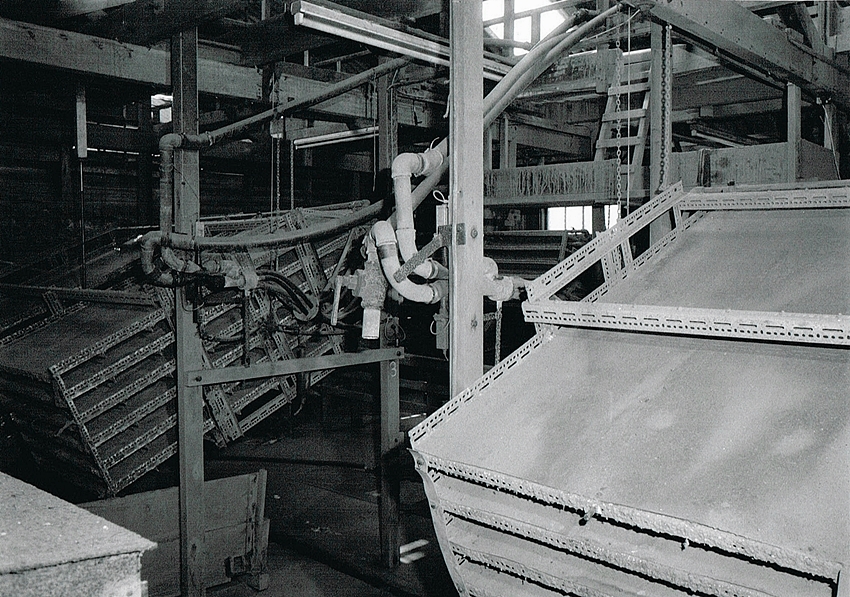

Built at Geevor with dexion angle and sheets of mylar. Clifford Tresize had a lot to do with these at the time. These frames were suspended with an electric motor driving an out-of-balance weight, which caused the frame to oscillate. Also the speed and amplitude were adjustable.

Tin slimes were fed onto the decks and the heavy material would settle on the decks. Then after a pre-set time interval a pneumatic cylinder would tilt the fame with water washing the settled material off the decks into a trough. The trough then fed the material onto the decks of shaking tables to concentrate the tin ore.

In the box are octal base timers for the feed on / feed off / wash water on / wash water off / tilt up / tilt down. To the right of this electronics box are the pneumatic water trap, filter / regulator & solenoid operated control valves. Note the scrap men have cut the power cable off.

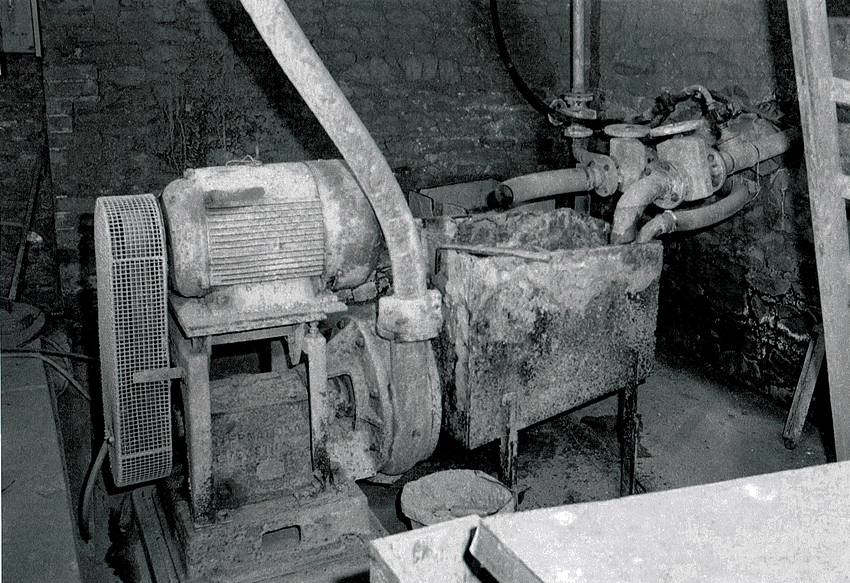

The Buells rotary dryer is a smaller version of the china clay dryers at Par docks. The revolving furnace tube slopes slightly down to the left. Wet tin concentrate is fed by auger into the right hand end of the dryer, the dryer tube has a series of lifter bars running the length. As the wet tin concentrate tumbles along the tube the water is driven of by the heat as steam.

The dry tin concentrate falls out of the left hand end of the drum into an auger that lifts it to the bagging hopper, ready to be bagged for shipment to the smelter. The products of combustion, hot air and steam plus entrained very fine particles of concentrate are drawn by a fan through a cyclone where the heavier particles drop into a rotary airlock then dropped into the auger to the bagging hopper.

The very fine particles pass up through the cyclone vortex finder and down through a “wet-arrestor” where these fine particles are caught on a water sprayed matrix of short ceramic tubes. Then into a large tank filled with water to provide a water seal for the negative pressure caused by the fan. Geevor made there own fans, several being built by Roy Angove also a couple by myself.

The walk around the site is extraordinary, the patterns and textures to be seen are superb. Taken in black and white I think the images do justice to the fascination of the remaining buildings and machinery.

All the information on the images in the 10 Galleries has been supplied by Mr Bob Orchard.He loved the mine and everything it stood for. Bob, you have my thanks and respect.