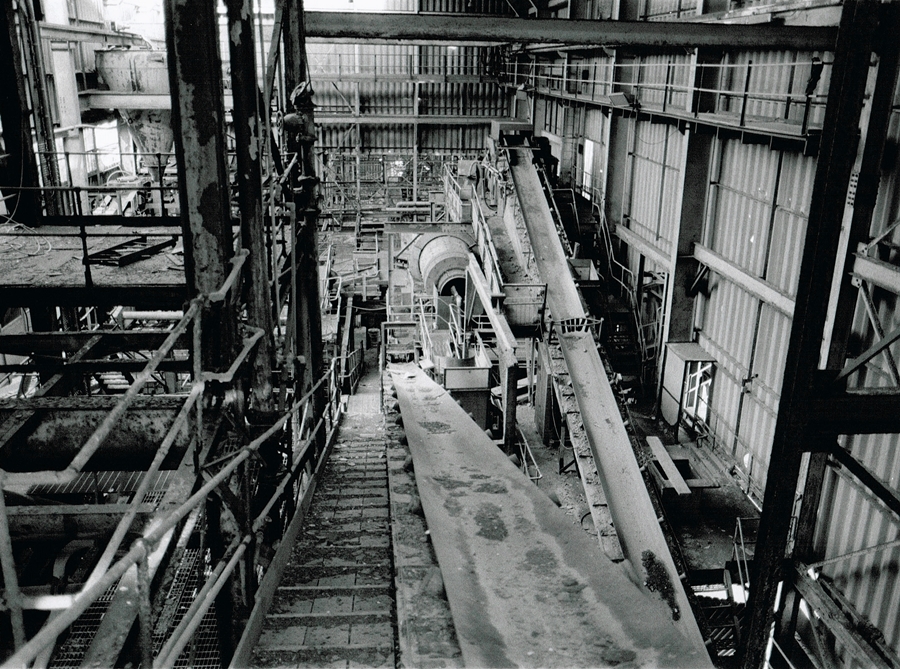

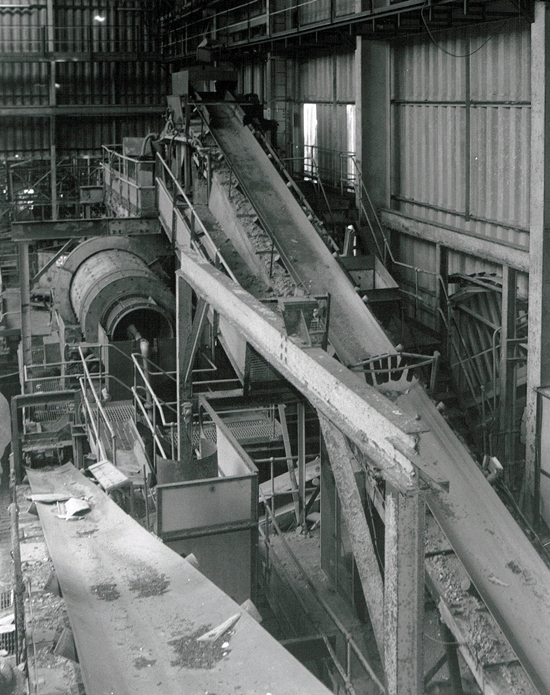

South Crofty Mine Mill 1: This is the first of three pages that contains images taken inside of the now demolished mill. So the new road goes through the centre of where these buildings used to stand.

I was granted access before the mine closed, even then a hardhat was needed and extreme care had to be taken on the upper floors and gantry. However it was an amazing place to wander around.

The “Modern” Mill at South Crofty had major refurbishments during the 1970’s. Then again in 1982 when a new “Recovery Section” was commissioned. This allowed an increase in the milling capacity to about 1100 Tonnes per day. The mill was fed from various sources the main being South Crofty 85%, also Pendarves Mine and dump reprocessing supplied the balance.

On the 380Fm level Cooks Shaft there was a 30″ x 20″ rock crusher. This would reduce the mined material to a size of less than 200mm. It made more sense to crush underground so more material would fit into a skip for hoisting up the shaft.

Once at the top of the shaft the mined material was fed into the three 750 Tonne Coarse Ore storage bins. From there it was fed into the mill.

After the mill was closed the bins were still in use to store the ore. But from here it was loaded into trucks and taken to the mill at Wheal Jane. This was in operation until the mine closed in 1998.