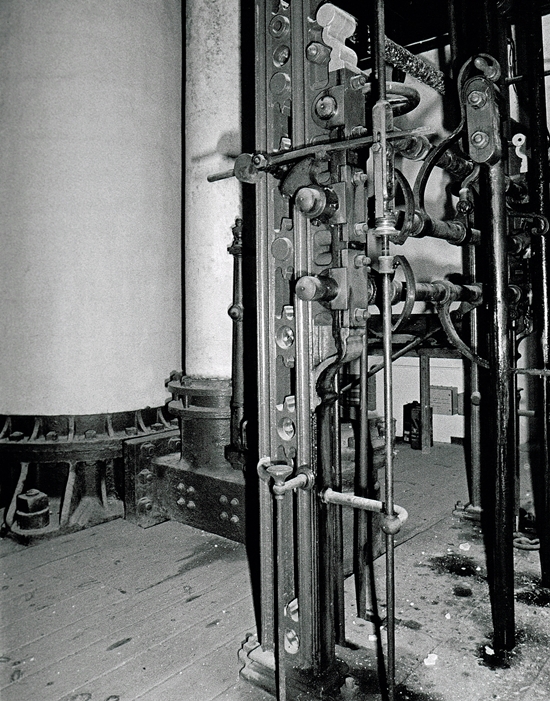

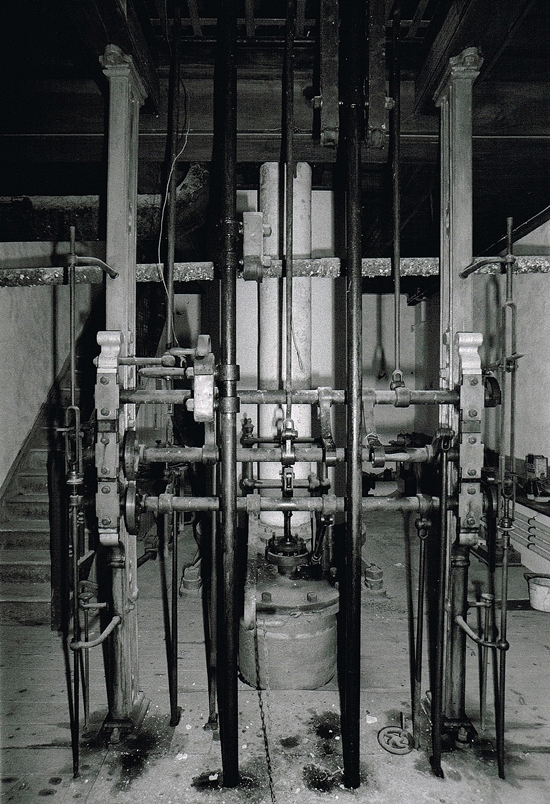

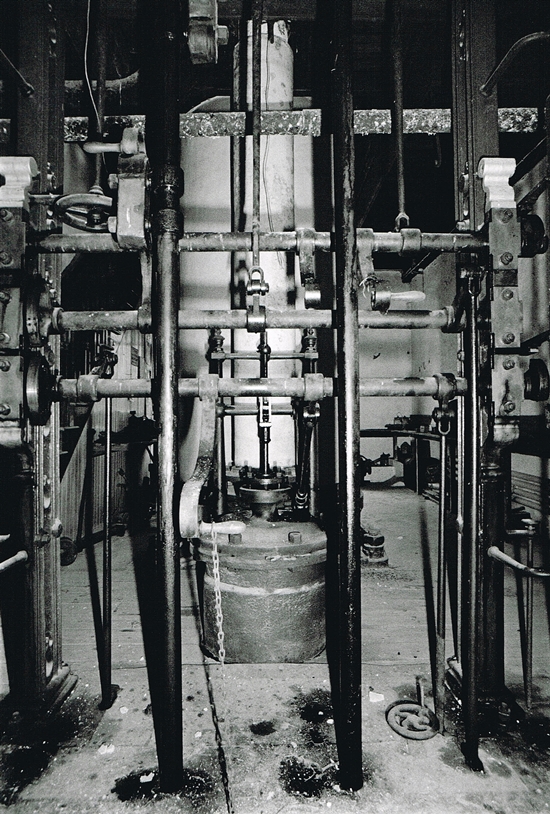

Parkandillick Gallery 1: This page has images taken on the first floor of the Parkandillick Engine House. On walking through the door the first thing seen is the base of the cylinder.

The engine is single-acting and fitted with a jet condenser. This is outside between the house and the shaft, with the air pump and feed pump to the boiler driven from the beam. Steam acts on the top of the piston. In turn this is aided by vacuum from the condenser beneath.

This pulled the indoor end of the beam down, raising the pump rod, also the plunger in the shaft. The return stroke was effected by the weight of the pump rod. Part of the weight was also counteracted by a balance box to ensure smooth operation. The engine did about six strokes per minute also lifting 125 gallons of slurry at each stroke.

The present cylinder is a replacement made by Bartle’s Foundry, Carn Brea. This was required when the engine was moved. It currently lacks a steam jacket. Steam was supplied by a single Lancashire boiler which also still remains in the Boiler House.

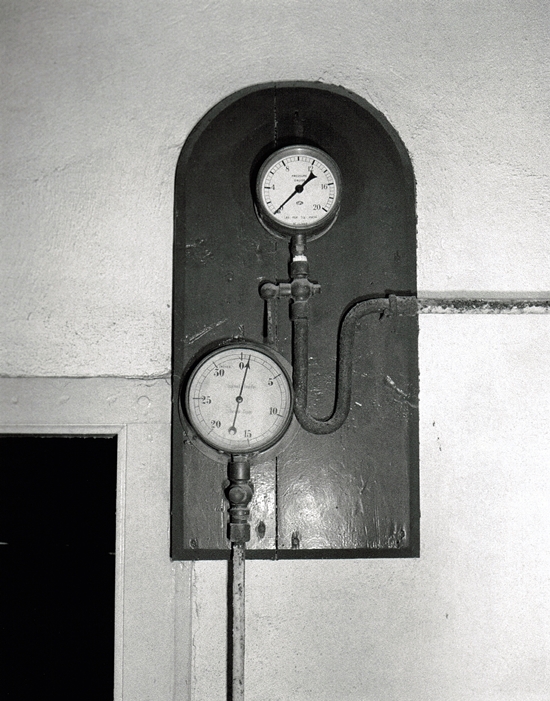

Until recently the engine was run while under air pressure. This was supplied by a two stage centrifugal fan, delivering 700 cu.ft.of air per minute. Because the engine requires a load to operate, the top sections of the pump rod were retained when the pitwork was dismantled. Consequently, the nose of the beam weighs in at around a ton. (Courtesy of The Trevithick Society)

Furthermore, the engine was known fondly as Elizabeth by those who worked her.

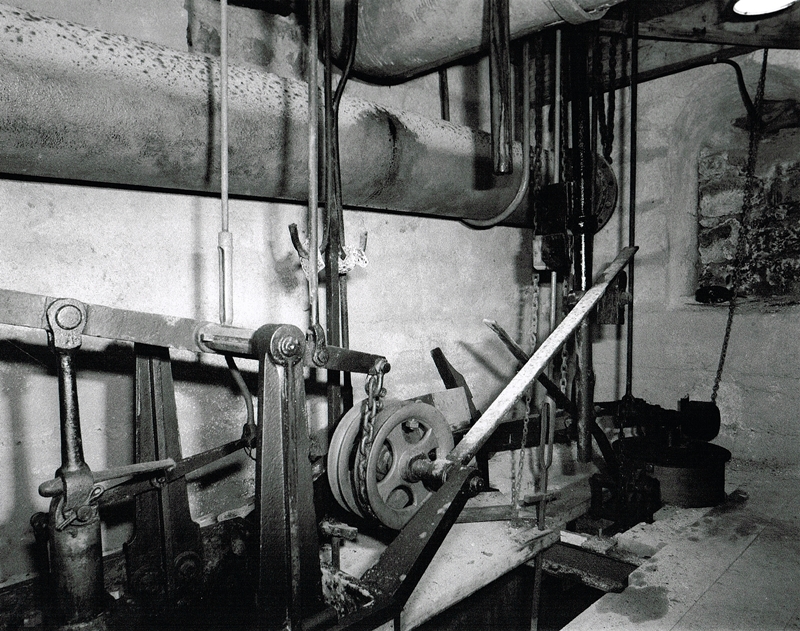

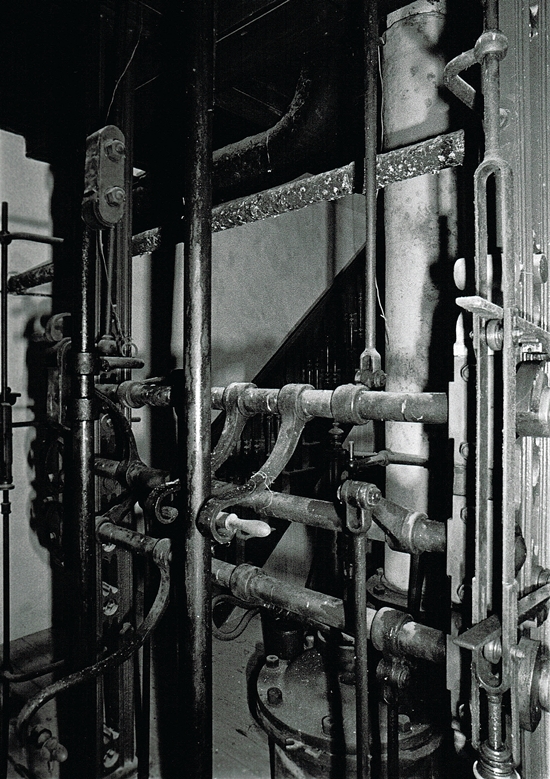

Under steam the engine would have been started by hand. Achieved by using the long handles to work the valves until full vacuum was reached in the condenser. Under air, the controls were left set, the engine started itself once working air pressure was reached.

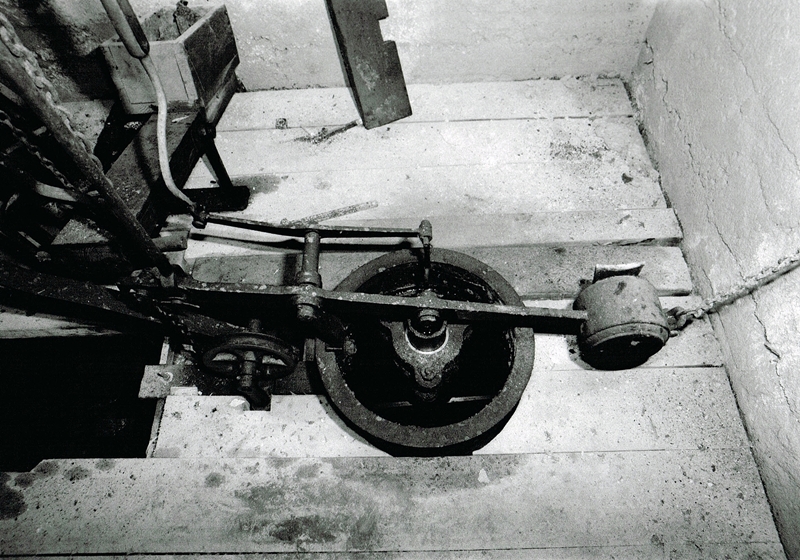

Finally, the stroking of the engine was controlled by two water-filled cataracts beneath the floor, just as when in steam. (Courtesy of The Trevithick Society)